Safety light curtains, Safety light grids

Light curtain for maximum safety at machine workstations

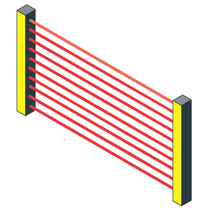

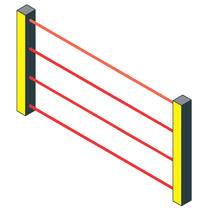

Wherever people work with machines, safety plays a central role. Reliable protective measures are mandatory, especially in automated systems with potential danger points. Electro-sensitive protective equipment (ESPE) offers an effective solution here: it immediately recognises the penetration of body parts into hazardous areas - without any physical contact. The finer the arrangement of the light beams, the more precise the detection. A particularly powerful type of this technology is the light curtain.

A safety light curtain for safeguarding danger zones

A safety light curtain is a highly developed electronic protective device. Its detection capability is based on precise sensor technology: the closer the light beams are to each other, the smaller the objects that can be recognised - right down to hands and individual fingers. With a resolution of less than 40 mm, a light curtain enables significantly finer detection compared to the classic light grid and therefore ensures maximum machine safety. In accordance with DIN EN ISO 13855, biometric reference values apply - around 14 mm for finger protection and up to 30 mm for hand recognition.

SLC series light curtains

The SLC series safety light curtains from Schmersal are specially designed to safeguard individual hazardous points or entire danger areas - for example in robot cells, presses, palletising systems or die-casting machines. Available with resolutions for hand or finger protection (30 or 14 mm), they are suitable for a wide range of industrial applications in the context of Industry 4.0. The devices fulfil degree of protection IP67 and are therefore protected against dust and temporary immersion. For demanding environments, such as in the food or pharmaceutical industries, variants with an extended IP69 degree of protection are available - ideal for regular high-pressure or steam jet cleaning.

Light curtain from Schmersal: Blanking and muting as additional functions

Every safety light curtain from Schmersal is available with different functions. These include:

- Blanking: to hide selected areas of the protective field

- Muting: for temporary bridging of the safety guard

These functions are used when materials are fed into the machine, workpieces enter the protective field for processing or products need to be removed. With the help of the relevant accessories and the appropriate safety module as an evaluation unit, each light curtain can also be extended to form a complete safety system.

Secure your machine workstations now with a modern light curtain

Whether for new systems or for retrofitting existing machines - a light curtain is an efficient solution for greater machine safety and reliable accident prevention. Get advice now and find the right safety device for your application. Our team of experts will be happy to assist you with the selection and integration of your electronic safety guard!

Frequently asked questions about light curtains

What is a light curtain?

A light curtain is a non-contact safety or automation system that consists of a series of infrared light beams emitted between a transmitter and a receiver. These infrared light rays form an invisible protective field. If one of the beams is interrupted - by a hand or an object, for example - the system recognises the interruption immediately and triggers a defined reaction, such as stopping a machine. Light curtains are frequently used in industrial production and automation.

How does a light curtain work?

A light curtain consists of a transmitter, which emits infrared light beams, and a receiver, which detects these infrared light beams. This creates an invisible grid between the transmitter and receiver. If one or more beams are interrupted, the receiver registers the change and transmits a signal to the connected control unit. This signal can, for example, trigger an immediate machine stop to protect people or objects. The technology is based on optoelectronic sensors and is particularly reliable and fast.

What safety standards must a light curtain fulfil?

Light curtains must fulfil strict safety requirements, especially if they are used in hazardous machine environments. The most important standards and specifications are

- Machinery Directive 2006/42/EC - regulates basic safety requirements in the EU

- EN ISO 13849-1 - describes the requirements for functional safety

- Safety categories 2 to 4 - depending on risk and area of application

- Performance Level (PL) a-e - whereby PL "e" offers the highest level of safety

- MV specifications - protection against electromagnetic interference

Only a safety light curtain that fulfils these conditions may be used in safety-relevant areas.

Who needs a light curtain?

Light curtains are needed wherever people could come into contact with dangerous machinery. Typical users are companies from the automotive industry, the packaging industry, metal working industry and logistics. Light curtains are also widely used in presses, robots and high-rack storage systems. They serve to protect operating personnel and at the same time enable interruption-free operation, as no physical protection such as a grille or door is required. They are also used in access control and quality insurance.

How do you install a light curtain?

The installation of a light curtain involves several steps and should be planned professionally:

- Positioning: Mount the transmitter and receiver opposite each other, with a clear line of sight

- Alignment: precise adjustment to avoid signal loss

- Mounting: Attachment to stable brackets or machine parts

- electrical connection: Integration into the machine control system, e.g. via a safety relay

- Configuration: Adjust settings such as range, resolution or muting

- Acceptance check: Function test and documentation after installation

Safety light curtains must be inspected annually and the inspection must be documented.

.png?id=497683c97d2c2689df20070a5453bdbb)