EX-CSS 8-180-2P+D-M-L-3G/D-10M

EX-CSS 8-180-2P+D-M-L-3G/D-10M

- Pre-wired cable 7-pole

- Comfortable diagnostics through sensor LED and electronic signalling output

- Thermoplastic enclosure

- Electronic contact-free, coded system

- Ø M18

- Misaligned actuation possible

- High repeat accuracy of the switching points

- Max. length of the sensor chain 200 m

- Early warning when operating near the limit of the sensor's hysteris range

- Self-monitoring series-wiring of 16 sensors

- 2 short-circuit proof PNP safety outputs

- Explosion protection for ATEX Zones 2 and 22

Ordering data

| Product type description |

EX-CSS 8-180-2P+D-M-L-3G/D-10M |

| Article number (order number) |

103011483 |

| EAN (European Article Number) |

4030661478425 |

| eCl@ss number, version 12.0 |

27-27-46-01 |

| eCl@ss number, version 11.0 |

27-27-24-03 |

| eCl@ss number, version 9.0 |

27-27-24-03 |

| ETIM number, version 7.0 |

EC001829 |

| ETIM number, version 6.0 |

EC001829 |

Approvals - Standards

| Certificates |

TÜV UKCA ATEX (Konformitätserklärung) |

Explosion protection

| Explosion protection: regulations |

EN IEC 60079-0 EN IEC 60079-15 EN 60079-31 |

| Explosion protection zones |

2 22 |

| Explosion protection category |

3G 3D |

| Explosion protection designation |

D II 3G Ex nA IIB T6 Gc X D II 3G Ex nA IIC T6 Gc X D II 3D Ex tc IIIC T70°C Dc X |

| Manufacturer declaration |

ATEX Zone 2 and 22 |

General data

| Working principle |

誘導型 |

| Housing construction form |

シリンダー型、ネジ式 |

| Installation conditions (mechanical) |

不適切な |

| Sensor topology |

直列配線用センサー |

| Housing material |

グラスファイバー強化熱可塑性樹脂 |

| Active area |

グラスファイバー強化熱可塑性樹脂 |

| Material of the nuts |

グラスファイバー強化熱可塑性樹脂 |

| Reaction time, maximum |

30 ms |

| Duration of risk, maximum |

30 ms |

| Gross weight |

533 g |

General data - Features

| Short circuit detection |

Yes |

| Cross-circuit detection |

Yes |

| Safety functions |

Yes |

| Integral system diagnostics, status |

Yes |

| Number of semi-conductor outputs with signaling function |

1 |

| Number of fail-safe digital outputs |

2 |

| Number of series-wiring of sensors |

16 |

| Safety classification |

| Vorschriften |

EN ISO 13849-1 EN IEC 61508 |

| Performance Level, up to |

e |

| Category |

4 |

| PFH value |

2.50 x 10⁻⁹ /h |

| Safety Integrity Level (SIL), suitable for applications in |

3 |

| Mission time |

20 Year(s) |

Mechanical data

| Impact energy, maximum |

2 J |

| Tightening torque of nuts, maximum |

3 Nm |

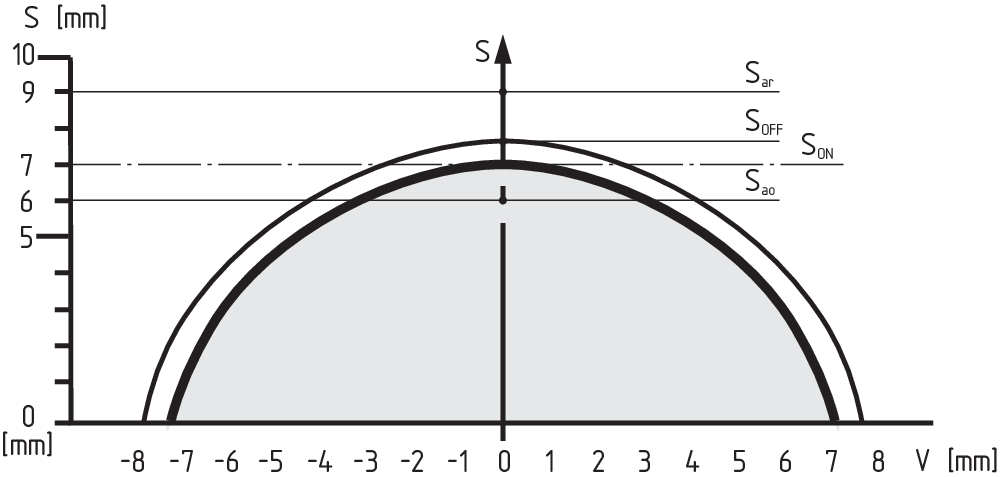

Mechanical data - Switching distances

| Switch distance, typical |

8 mm |

| Assured switching distance "ON" Sao |

7 mm |

| Assured switching distance "OFF" Sar |

10 mm |

| Note (switching distance) |

All switching distances in accordance EN IEC 60947-5-3 |

| Hysteresis (Switching distance), maximum |

0.7 mm |

| Repeat accuracy R |

0.2 mm |

Mechanical data - Connection technique

| Length of cable |

10 m |

| Termination |

ケーブル |

| Terminal connector, Output |

7芯 |

| Wire cross-section |

0.25 mm2 |

| Wire cross-section |

23 AWG |

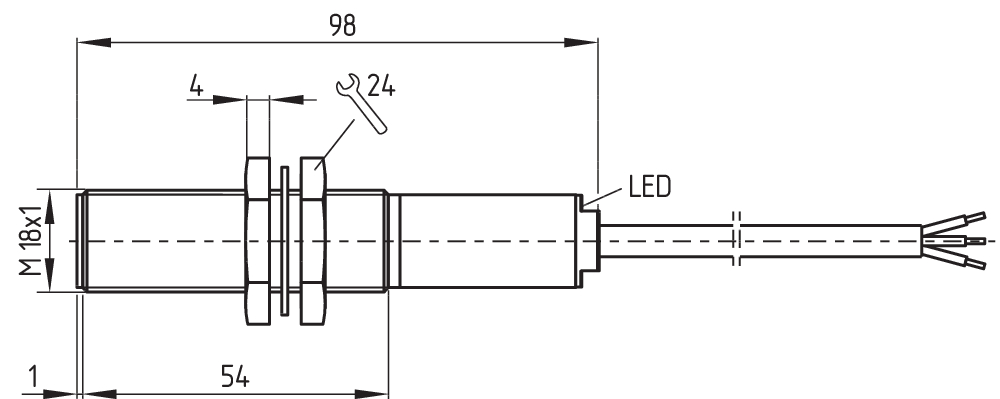

Mechanical data - Dimensions

| ISO thread of the sensor |

M18 |

| width across flats |

24 BK |

| Length of sensor |

92 mm |

Ambient conditions

| Degree of protection |

IP65 IP67 |

| Ambient temperature |

-25 ... +40 °C |

| Storage and transport temperature |

-25 ... +85 °C |

| Resistance to vibrations |

10 ~ 55 Hz, 振幅 1 mm |

| Restistance to shock |

30 g / 11 ms |

| Protection class |

II |

Ambient conditions - Insulation values

| Rated insulation voltage Ui |

32 VDC |

| Rated impulse withstand voltage Uimp |

0.8 kV |

| Overvoltage category |

III |

| Degree of pollution |

3 |

Electrical data

| Operating voltage |

24 VDC -15 % / +10 % |

| No-load supply current I0, typical |

50 mA |

| Rated operating voltage |

24 VDC |

| Operating current |

1,000 mA |

| Switching frequency, approx. |

3 Hz |

| Utilisation category DC-12 |

24 VDC / 0.05 A |

Electrical data - Safety digital outputs

| Design of control elements |

PNP型 |

| Voltage drop Ud, maximum |

0.5 V |

| Leakage current Ir, maximum |

0.5 mA |

| Voltage, Utilisation category DC-12 |

24 VDC |

| Current, Utilisation category DC-12 |

0.5 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

0.5 A |

Electrical data - Digital Output

| Design of control elements |

PNP型 |

Electrical data - Diagnostic outputs

| Voltage drop Ud, maximum |

4 V |

| Voltage, Utilisation category DC-12 |

24 VDC |

| Current, Utilisation category DC-12 |

0.05 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

0.05 A |

Status indication

| Note (LED switching conditions display) |

Multi-coloured LED: Green, Red, Yellow |

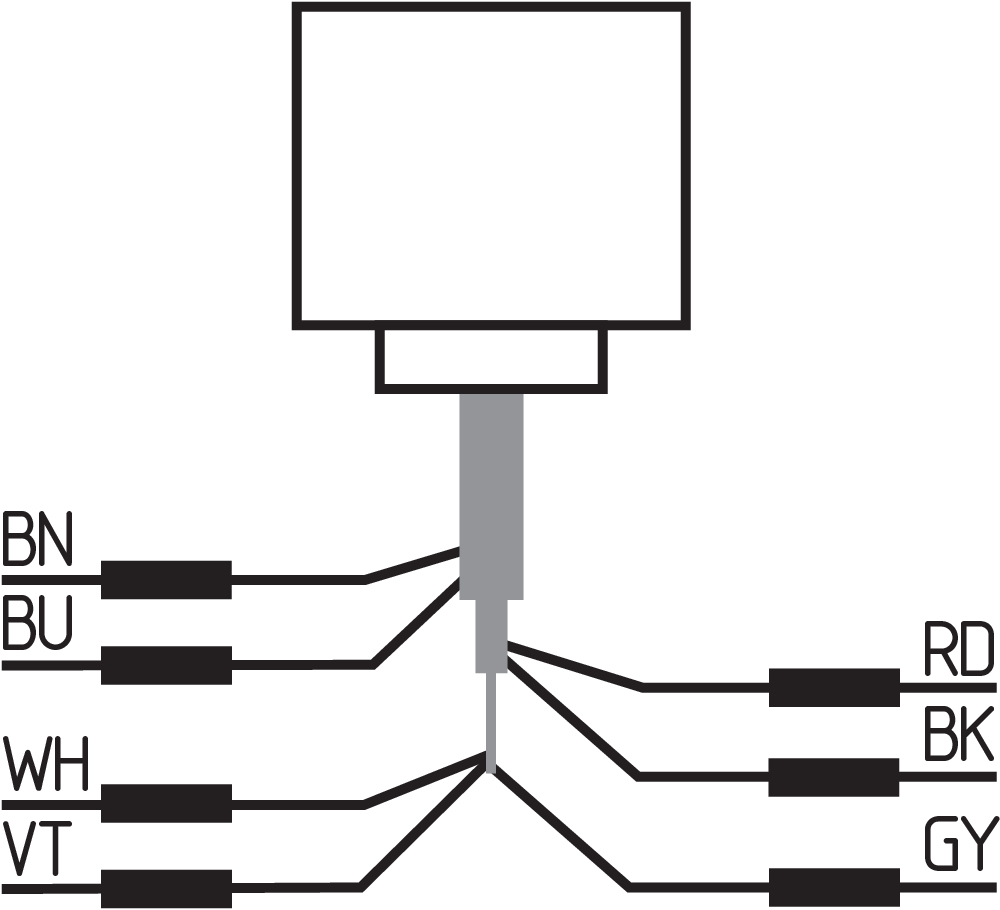

Pin assignment

| PIN 1 |

A1 Ue Brown |

| PIN 2 |

Y2 Safety output 2 red |

| PIN 3 |

A2 GND Blue |

| PIN 4 |

Y1 Safety output 1 Black |

| PIN 5 |

X1 Safety input 1 violet |

| PIN 6 |

X2 Safety input 2 White |

| PIN 7 |

Signalling output Grey |

Scope of delivery

| Scope of delivery |

Actuator must be ordered separately. |

| Scope of delivery of mounting material |

ナット M18 x 1 2個 |

Accessory

| Recommendation (actuator) |

CST 180-1 CST 180-2 |

Note

| Note (General) |

Series-wiring of sensors: 16 safety sensors can be switched in series with self-monitoring. In this case, the dual-channel output of a sensor is switched to/inserted into the input of the next sensor. This does not affect the category 4 in accordance with EN ISO 13849-1. The voltage drop over a long sensor chain should be taken into account when planning cable routing. Operating voltage, cross-section and length of the cable, temperature, number of sensors connected, but also the input load of the control monitor all affect the voltage drop over the sensor chain. |

言語フィルター

データシート

Operating instructions and Declaration of conformity

TÜV certification

UKCA certificate

Wiring example (electr. wiring)

Brochure

SISTEMA-VDMA library

Adobe Readerの最新版をダウンロードしてください

Product picture (catalogue individual photo)

Dimensional drawing basic component

Diagram

Characteristic curve

Family picture (group photo)

| UK Declaration of Conformity |  |

| Company: | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby, under sole responsibility, certify that the hereafter described components both in their basic design and construction conform to the relevant statutory requirements, regulations and designated standards of the United Kingdom. |

| Name of the component: | EX-CSS 8-180 |

| Type: | See ordering code |

| Marking: | D II 3G Ex nA IIC T6 Gc X D II 3D Ex tc IIIC T70°C Dc X |

| Description of the component: | Non-contact safety sensor |

| Relevant legislation: | Supply of Machinery (Safety) Regulations | 2008 |

| Electromagnetic Compatibility Regulations | 2016 | |

| Equipment and Protective Systems intended for use in Potentially Explosive Atmospheres Regulations | 2016 | |

| The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations | 2012 |

| Designated standards: | EN 60947-5-3:2013, EN ISO 14119:2013, EN ISO 13849-1:2015, EN 61508 parts 1-7:2010, EN IEC 60079-0:2018, EN IEC 60079-15:2019, EN 60079-31:2014 |

| Approved body for Type Examination: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| Type examination certificate: | 01/205/5874.00/21 |

| The conformity assessment procedure for explosion protection was carried out in accordance with Article 13 of Directive 2014/34/EU, under the responsibility of the manufacturer K.A. Schmersal GmbH & Co. KG. |

| UK-Importer / Person authorised for the compilation of the technical documentation: | Schmersal UK Ltd. Paul Kenney Unit 1, Sparrowhawk Close Enigma Business Park Malvern, Worcestershire, WR14 1GL |

| Place and date of issue: | Wuppertal, August 12, 2022 |

|

| Authorised signature Philip Schmersal Managing Director |

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | EX-CSS 180 |

| Type: | See ordering code |

| Marking: | D II 3G Ex nA IIC T6 Gc X |

| D II 3D Ex tc IIIC T70°C Dc X |

| Description of the component: | Non-contact safety sensor |

| Relevant Directives: | Machinery Directive | 2006/42/EC |

| EMC-Directive | 2014/30/EU | |

| Explosion Protection Directive (ATEX) | 2014/34/EU | |

| RoHS-Directive | 2011/65/EU |

| Applied standards: | DIN EN 60947-5-3:2014 EN 60079-0:2012 + A11:2013 EN 60079-15:2010 EN 60079-31:2014 |

| Notified body, which approved the full quality assurance system, referred to Appendix IV, 2014/34/EU: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, May 2, 2017 |

|

| Authorised signature Philip Schmersal Managing Director |

Schmersal India Pvt. Ltd., Plot No - G-7/1, Ranjangaon MIDC, Tal. - Shirur, Dist.- Pune 412 220

データと詳細は完全にチェックされました。画像は元の画像と異なる場合があります。技術的なデータはマニュアルで見られます。技術的に変更されたり、エラーの可能性があります。

Generated on 2025/04/21 2:28

.png?id=497683c97d2c2689df20070a5453bdbb)