Application:

The solenoid interlocks of the AZM series have been designed to prevent, in conjunction with the control part of a machine, e.g. fail-safe delay timers or fail-safe standstill monitors, sliding, hinged and removable safety guards such as fences, flaps or doors, from being opened before hazardous conditions (e.g. run-on movements) have been eliminated.

These solenoid interlocks are also used for cases in which the opening of a guarding device represents a non-permissible intrusion in a production process.

Design and mode of operation:

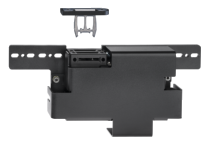

On the AZM range solenoid interlocks, the switching element with interlock is not physically connected to the actuator but functionally brought together or separated on switching. When the safety guard is opened in the unlocked condition, the actuator is separated from the base unit. During this process, the NC contacts are positively opened and the NO contacts closed.

Interlocking is carried out by means of a blocking bolt / latching bolt. This latching bolt blocks the actuator so that it cannot be withdrawn from the interlock. The machine control is only enabled when the actuator has been inserted into the interlock and the latching bolt is in blocking position. This is ensured by the contact monitoring of the latching bolt.

There are two modes of interlocking. The "Power to unlock" principle is where the locking bolt is held into position with a spring. When the de-interlocking coil is energised, the interlock is removed and the NC contacts opened. The protection equipment can be opened. For "Power to lock"1) the mode of operation is reversed.

The solenoid interlocks EX-AZM 161, 170 and 415 are fitted with protection against incorrect locking. Depending on the type of unit, an individual coding of the actuator are possible.

The solenoid interlocks can be fitted in any desired mounting position. Protection class of the solenoid interlocks is IP 54, IP 65 or IP 67.

1) In accordance with the policy of the German Technical Assessors, these interlock may only be used after a thorough evaluation of the accident risk, since the guarding device can immediately be opened on failure of the electrical power supply.