Magnetic safety sensors

BNS 16

- Thermoplastic enclosure

- Suitable for food processing industry

- Concealed mounting possible

- 52 mm x 90 mm x 32 mm

- Long life

- no mechanical wear

- Insensitive to transverse misalignment

- Insensitive to soiling

- Coded reed contact safety switch

BNS 260

- Thermoplastic enclosure

- small body

- Concealed mounting possible

- 26 mm x 36 mm x 13 mm

- Long life

- no mechanical wear

- Insensitive to transverse misalignment

- Insensitive to soiling

BNS 36

- Thermoplastic enclosure

- Long life

- no mechanical wear

- 88 mm x 25 mm x 13 mm

- Concealed mounting possible

- Insensitive to transverse misalignment

- Insensitive to soiling

BNS 40S

- Stainless steel enclosure

- Cable connection suitable for the food industry

- Concealed mounting possible

- 88 mm x 27 mm x 14,5 mm

- Long life

- no mechanical wear

- Insensitive to soiling

- Insensitive to transverse misalignment

- Suitable for food processing industry

BNS-B20

- Thermoplastic enclosure

- Non-contact safety switch

- Does not protrude into the door opening

- 119,5 mm x 140 mm x 43,3 mm

- Substitutes door-handle and safety switch, no further door fittings required

- Modern and symmetric design

- Tamper-proof because of integral coded safety sensor

- Ergonomic operation

- Suitable for hinged and sliding guards

- No protruding actuator

- Simple mounting with 4 Screws

BNS 250

- Thermoplastic enclosure

- small body

- Concealed mounting possible

- 33 mm x 25 mm x 13 mm

- Long life

- no mechanical wear

- Insensitive to transverse misalignment

- Insensitive to soiling

BNS 33

- Thermoplastic enclosure

- Concealed mounting possible

- Insensitive to transverse misalignment

- 88 mm x 25 mm x 13 mm

- Long life

- no mechanical wear

- Insensitive to soiling

BNS 30

- Metal enclosure

- Long life

- Suitable for food processing industry only in combination with BPS 303 SS

- no mechanical wear

- Ø M30

- Insensitive to transverse misalignment

- Insensitive to soiling

- With integral evaluation

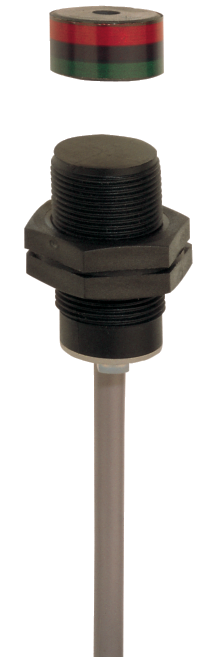

BNS 300

- Thermoplastic enclosure

- Long life

- Suitable for food processing industry only in combination with BPS 303

- no mechanical wear

- Ø M30

- Insensitive to transverse misalignment

- Insensitive to soiling

- With integral evaluation

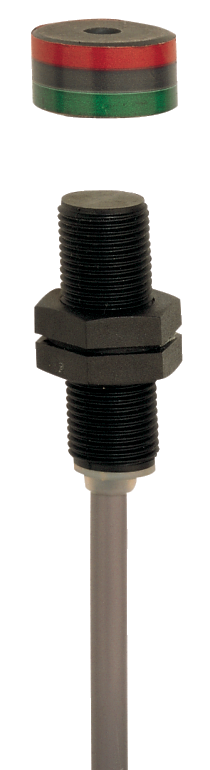

BNS 303

- Thermoplastic enclosure

- Long life

- Suitable for food processing industry only in combination with BPS 303 SS

- no mechanical wear

- Ø M30

- Insensitive to transverse misalignment

- Insensitive to soiling

BNS 333

- Thermoplastic enclosure

- Long life

- Suitable for food processing industry only in combination with BPS 303

- no mechanical wear

- 40 mm x 112 mm x 40 mm

- Insensitive to transverse misalignment

- Insensitive to soiling

- Wiring compartment

- With integral evaluation

BNS 120

- Thermoplastic enclosure

- Suitable for food processing industry only in combination with BP 15 SS

- Particularly large switching distance

- Ø M12

- Long life

- no mechanical wear

- Insensitive to transverse misalignment

- Insensitive to soiling

- uncoded, concealed installation according to ISO 14119

BNS 180

- Thermoplastic enclosure

- Suitable for food processing industry only in combination with BP 15 SS

- Particularly large switching distance

- Ø M 18 x 1

- Long life

- no mechanical wear

- Insensitive to transverse misalignment

- Insensitive to soiling

- uncoded, concealed installation according to ISO 14119

MAGNETIC SAFETY SENSORS

Unlike category 2 electromechanical safety switches, safety sensors enable contactless position monitoring of safety doors. This is an advantage for machines that are exposed to high levels of dirt and dust. The sensors are also frequently used in hygiene-sensitive areas, such as the food industry. A basic distinction must be made between electronic and magnetic safety sensors. What both have in common, however, is that they each have a sensor and a target that communicate with each other without contact. The machine can then be put into operation when the sensor detects the target and the safety door and safety circuit are closed.MAGNETIC SAFETY SENSORS OF THE BNS SERIES

The safety solenoid switches of the BNS-series use the proven principle of safe magnet technology. The switching devices are electromagnetic, non-contact and operate on two channels. As they have two safety contact paths, they are also fail-safe. The sensor can only be actuated with the corresponding target, but not with a conventional magnet, which is due to the combination and arrangement of the reed tubes in the sensor. This ensures a high level of protection against tampering. Despite their compact design, the BNS sensors achieve high switching distances. Concealed mounting is also possible, as the sensor technology works through plastic and even stainless steel covers.

DIFFERENT DESIGNS OF MAGNETIC SAFETY SENSORS IN THE ONLINE CATALOGUE

Schmersal offers the user a wide range of different designs, including sensors with stainless steel housings. All of the Schmersal Group's safety sensors have IP65 degree of protection at a minimum, are dust-tight and protected against water jets from all directions. When used in conjunction with a corresponding safety relay module, they can also achieve Performance Level d or e in accordance with EN ISO 13849-1. In its comprehensive online catalogue, the Schmersal Group provides detailed product information on the individual magnetic safety sensors.

.png?id=497683c97d2c2689df20070a5453bdbb)