Interruptores de Paro de Emergencia por tracción de cable

ZQ 215

- Caja metélica

- Diseño a EN 50047

- Técnica de conexión rápida mediante bridas de conexión girables en 45º

- Entrada de cable 1 x M20 x 1,5

ZQ 315

- Caja metélica

- Técnica de conexión rápida mediante bridas de conexión girables en 45º

- Entrada de cable 1 x M20 x 1,5

- Diseño a EN 50041

ZQ 700

- Caja de termoplástico

- Accionamiento por un lado / Long. del cable hasta 10 m

- Pulsador de rearme

- Indicador de posición

- Amplia zona de conexionado

- Anclaje a prueba de torsión

- Detecta tracción o rotura del cable

- Solamente una fuerza única para cables con longitud hasta 10 m

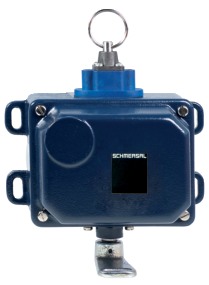

ZQ 900

- Caja metélica

- Accionamiento por un lado / Long. del cable hasta 75 m

- Pulsador de rearme

- Indicador de posición

- Diseño robusto

- Amplia zona de conexionado

- Anclaje a prueba de torsión

- Con retén de fuelle

- Detecta tracción o rotura del cable

ZQ 901

- caja de acero fino

- Accionamiento por un lado / Long. del cable hasta 75 m

- Pulsador de rearme

- Indicador de posición

- Diseño robusto

- Amplia zona de conexionado

- Anclaje a prueba de torsión

- Con retén de fuelle

- Detecta tracción o rotura del cable

- 3 entradas de cable M 20 x 1.5

RS655

- Caja metélica

- Detecta tracción o rotura del cable

- Protección IP66, IP67

- Terminal de conexión central

- Indicador de posición de conmutación mecánico

- Accionamiento por dos lados / longitud del cable hasta 2 x 100 m

RS656

- Caja de termoplástico

- Detecta tracción o rotura del cable

- Protección IP66, IP67

- Terminal de conexión central

- Indicador de posición de conmutación mecánico

- Accionamiento por dos lados / longitud del cable hasta 2 x 100 m

T3Z 068

- Caja metélica

- Accionamiento por dos lados / Long. del cable hasta 2 x 50 m

- Diseño robusto

- Baja fuerza de accionamiento

INTERRUPTORES DE PARO DE EMERGENCIA POR TRACCIÓN DE CABLE CON FUNCIÓN DE PARO DE EMERGENCIA FLEXIBLE

Los interruptores de Paro de Emergencia por tracción de cable se requieren en máquinas e instalaciones que no pueden ser aseguradas mediante cubiertas o resguardos de seguridad, etc. Se utilizan principalmente en instalaciones de transporte, así como en instalaciones de grandes dimensiones, como p.ej. en la industria del plástico, el reciclaje, y el procesamiento de madera. La amplia difusión de esta forma de interruptores de paro de emergencia se debe a la siguiente característica de seguridad que resulta decisiva: en un interruptor de seguridad por tracción de cable, al contrario del pulsador de paro de emergencia tipo seta, es posible accionar la función de paro de emergencia desde cualquier punto del cable.

INTERRUPTORES DE PARO DE EMERGENCIA POR TRACCIÓN DE CABLE: TAMBIÉN DISPONIBLES CON INTERFACE AS-I-SAW

Un interruptor de paro de emergencia por tracción de cable, en combinación con un relé de seguridad adecuado, puede ser utilizado hasta PL e según la norma EN ISO 13849-1. Este programa de productos del Grupo Schmersal incluye también variantes con interface AS-i-SaW (AS-Interface Safety at Work). Sobre la base del estándar abierto AS-International, se aprovechan las ventajas del sistema de bus sencillo y probado. Además, esta serie de interruptores está disponible en variantes que son adecuadas para el uso en atmósferas potencialmente explosivas y con temperaturas extremas. Por lo general se ha de distinguir entre interruptores de esta categoría con principio de funcionamiento a uno o dos lados.

DISEÑO Y PRINCIPIO DE FUNCIONAMIENTO DE LOS INTERRUPTORES DE PARO DE EMERGENCIA POR TRACCIÓN DE CABLE

Todos los interruptores de paro de emergencia por tracción de cable del Grupo Schmersal cumplen con las directrices de la norma EN ISO 13850, así como de la norma IEC 60947-5-5. La monitorización de la tracción o la rotura del cable son una característica estándar de los equipos. Los interruptores se ponen en estado operativo mediante el tensado previo del cable. En este estado de funcionamiento los contactos NC están cerrados y los contactos NA abiertos. Si se tira del cable o si se rompe, los contactos NC se abren y los contactos NA se cierran. Si, a continuación, el interruptor de paro de emergencia ha de volver al estado operativo, solo se podrá hacer de forma manual.

.png?id=3f3339435fb0327df6974792fc349718)