Pull-wire emergency stop switches

ZQ 215

- Metal enclosure

- Design to EN 50047

- Quick connection technology as connection terminals rotated by 45°

- cable entry 1 x M20 x 1,5

ZQ 315

- Metal enclosure

- Quick connection technology as connection terminals rotated by 45°

- cable entry 1 x M20 x 1,5

- Design to EN 50041

ZQ 700

- Thermoplastic enclosure

- one-side operation / wire up to 10 m long

- Release push button

- Position indicator

- Large wiring compartment

- Twisting of towing eye not possible

- wire pull and breakage detection

- One tension force for cable lengths up to 10 m

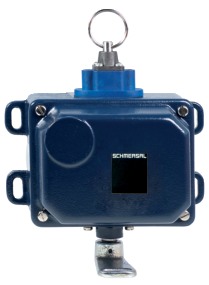

ZQ 900

- Metal enclosure

- one-side operation / wire up to 75 m long

- Release push button

- Position indicator

- Robust design

- Large wiring compartment

- Twisting of towing eye not possible

- External watertight collar

- wire pull and breakage detection

ZQ 901

- Stainless steel enclosure

- one-side operation / wire up to 75 m long

- Release push button

- Position indicator

- Robust design

- Large wiring compartment

- Twisting of towing eye not possible

- External watertight collar

- wire pull and breakage detection

- 3 cable entries M 20 x 1.5

RS655

- Metal enclosure

- wire pull and breakage detection

- Protection class IP66, IP67

- Central connection terminal

- Mechanical switching position indication

- two-side operation / wire up to 2 x 100 m

RS656

- Thermoplastic enclosure

- wire pull and breakage detection

- Protection class IP66, IP67

- Central connection terminal

- Mechanical switching position indication

- two-side operation / wire up to 2 x 100 m

T3Z 068

- Metal enclosure

- two-side operation / wire up to 2 x 50 m long

- Robust design

- Low actuating force

PULL-ROPE EMERGENCY STOP SWITCH WITH FLEXIBLE EMERGENCY STOP FUNCTION

Emergency pull-wire switches are required when machines and systems cannot be secured using safety doors or safety covers, etc. They are primarily used in transport and conveyor systems as well as on large-scale systems, e.g. in plastics technology, the recycling industry or wood processing. The widespread use of this type of emergency stop switch can be attributed to the following decisive safety feature: With a pull-wire emergency stop switch - in contrast to emergency stop control devices with mushroom pushbuttons - the emergency stop function can be triggered at any point along the wire.

EMERGENCY PULL-WIRE SWITCH: ALSO AVAILABLE WITH AS-I-SAW INTERFACE

An emergency pull-wire switch can be used in conjunction with a suitable safety evaluation system up to PL e in accordance with EN ISO 13849-1. This product programme of the Schmersal Group also includes variants with an integrated AS-Interface Safety-at-Work interface (AS-i-SaW). Based on the open AS-International standard, the advantages of the simple and proven bus system are utilised. This switch series is also available in versions that are suitable for use in potentially explosive atmospheres and at extreme temperatures. In general, a distinction must also be made between single-action and double-action switches in this category.

STRUCTURE AND MODE OF OPERATION OF THE EMERGENCY PULL-WIRE SWITCHES

All emergency pull-wire switches from the Schmersal Group comply with the guidelines of EN ISO 13850 and IEC 60947-5-5. Rope tension and rope breakage monitoring are included as standard. The switches are set to their operating state by pre-tensioning the cable. In this, the NC contacts are closed and, conversely, the NO contacts are open. If the cable is then pulled or breaks, the NC contacts open and the NO contacts close. If the emergency switch is then to be reset to the operating state, this can only be done by manually unlocking it.

.png?id=e5ef4d56dad486103335c34b5b46f1ce)