Belt alignment switch

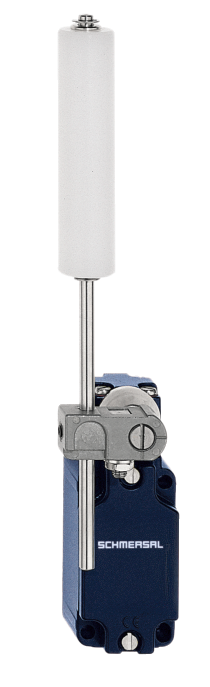

441 belt alignment switch

- Metal enclosure

- 2 Contacts

- 106 mm x 99 mm x 63 mm ( basic component)

- Suitable for heavy duty

T. 454 Belt alignment switch

- Cast iron enclosure, 2K paint

- Exterior parts made of stainless steel

- 2 switching angles (prewarning, deactivation)

HDS

- Platform concept with different function units

- Lever angle adjustable in 10° steps

- Protection class IP66, IP67

- Switching point setting

- Symmetry thanks to toothed, centrally located shaft

- Central connection terminal

- Wide range of alternative actuators

Application:

Belt alignment switches and slack-wire switches are suitable for use on material handling equipment.

The belt alignment switch is actuated, when the conveyor belt becomes misaligned. Depending on the plant set-up, this signal can be used to switch off the machinery or plant either to provide an automatic correction of the belt alignment.

Belt alignment switches and slack-wire switches are suitable for use on material handling equipment.

The belt alignment switch is actuated, when the conveyor belt becomes misaligned. Depending on the plant set-up, this signal can be used to switch off the machinery or plant either to provide an automatic correction of the belt alignment.

.png?id=dd4d6d28421d06b6d1d6f7ffec683d49)