EX-T4V7H335-11Y-RMS

EX-T4V7H335-11Y-RMS

| Product type description: EX-T(1) 335-(2)Y(3)-(4)-(5) |

| (1) | |

| S | Plunger S |

| R | Roller plunger R |

| H | Roller lever H |

| 10H | Rod lever 10H |

| 7H | Roller lever 7H |

| 7H-2138 | Roller lever 7H for position switches with safety function |

| 1K | Offset roller lever 1K |

| 3K | Angle roller lever 3K |

| (2) | |

| 11 | 1 NO contact/1 NC contact |

| 02 | 2 NC contact |

| 20 | 2 NO contacts (not suitable for safety applications) |

| (3) | |

| UE | Slow action with overlapping contacts |

| without | Slow action with staggered contacts |

| (4) | |

| 2138 | Roller lever 7H for position switches with safety function |

| (5) | |

| RMS | Roller made from brass |

- with brass roller

- Ex-Zone 1 and 21

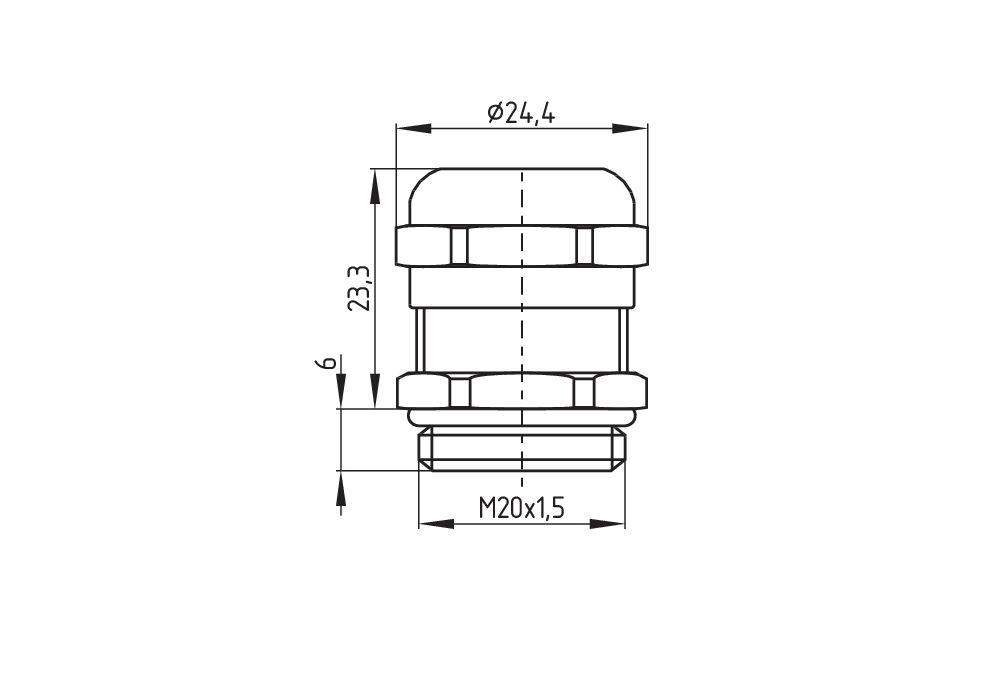

- 1 Cable entry M 20 x 1.5

- Metal enclosure

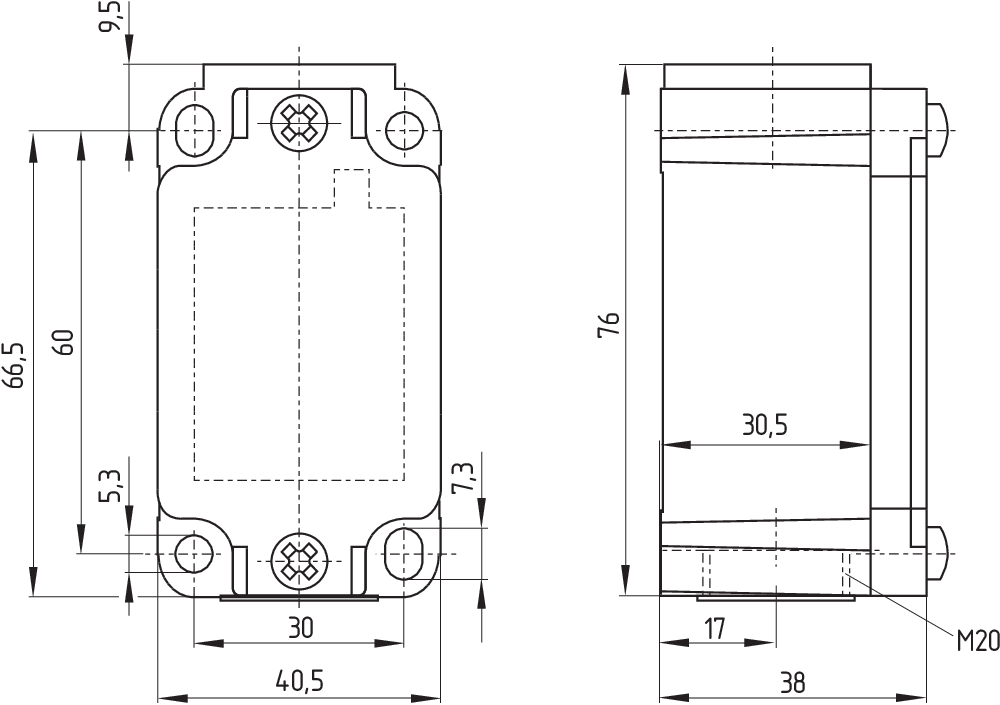

- 40,5 mm x 76 mm x 38 mm

- Good resistance to oil and petroleum spirit

- only for positioning tasks

- Mounting details to EN 50041

Ordering data

| Product type description |

EX-T4V7H335-11Y-RMS |

| Article number (order number) |

103040754 |

| eCl@ss number, version 12.0 |

27-27-06-01 |

| eCl@ss number, version 11.0 |

27-27-06-01 |

| eCl@ss number, version 9.0 |

27-27-06-01 |

| ETIM number, version 7.0 |

EC000030 |

| ETIM number, version 6.0 |

EC000030 |

Approvals - Standards

| Certificates |

cULus ATEX IECEx INMETRO PESO CCC-EX |

Explosion protection

| Explosion protection: regulations |

EN IEC 60079-0 EN 60079-1 EN 60079-7 EN 60079-31 |

| Explosion protection zones |

1 21 |

| Explosion protection category |

2G 2D |

| Explosion protection designation |

D II 2G Ex d e IIC T6 Gb D II 2D Ex tb IIIC T80°C Db |

General data

| Standards |

BG-GS-ET-15 EN IEC 60947-5-1 |

| Housing construction form |

Norm construction design |

| Housing material |

Metal, zinc die-cast |

| Housing coating material |

painted |

| Lever material |

Metal film |

| Material of the rod |

Plastic (Polyamid) |

| Gross weight |

400 g |

| Safety classification |

| Vorschriften |

EN ISO 13849-1 |

| Mission time |

20 Year(s) |

Safety classification - Safety outputs

| B10D Normally-closed contact (NC) |

20,000,000 Operations |

Mechanical data

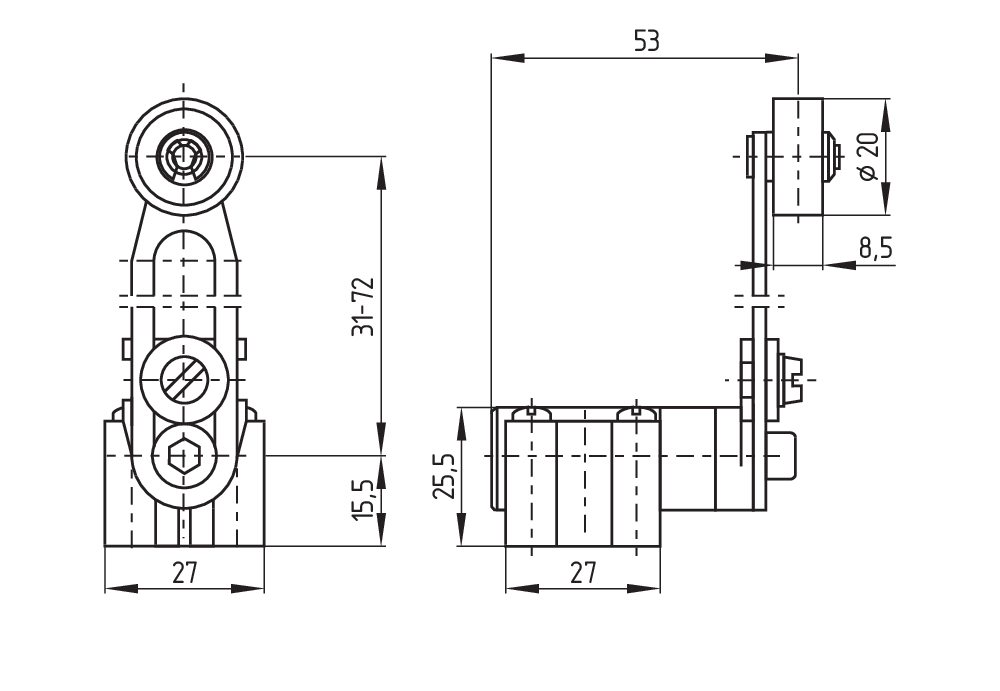

| Actuating element |

Rod lever |

| Roller material |

Brass |

| Mechanical life, minimum |

1,000,000 Operations |

| Impact energy, maximum |

7 J |

| Actuating speed, maximum |

1 m/s |

| Note (Actuating speed) |

Actuating speed with actuating angle 30° to switch axis |

Mechanical data - Connection technique

| Termination |

Screw terminals M20 x 1.5 |

| Cable cross-section of the cable glands, minimum |

7 mm |

| Cable cross-section of the cable glands, maximum |

12 mm |

| Cable section, minimum |

1 mm² |

| Cable section, maximum |

2.5 mm² |

| Note |

All indications including the conductor ferrules. |

| Wire cross-section |

13 AWG |

Mechanical data - Dimensions

| Length x Width x Height |

Height of sensor: 111.5 mm (without rod) |

| Length of sensor |

38 mm |

| Width of sensor |

40.5 mm |

Ambient conditions

| Degree of protection |

IP65 |

| Ambient temperature, maximum (Cable section 1mm2) |

+50 °C |

| Ambient temperature, maximum (Cable section 2.5mm2) |

+55 °C |

Ambient conditions - Insulation values

| Rated insulation voltage Ui |

250 VAC 500 V |

| Rated impulse withstand voltage Uimp |

4 kV |

Electrical data

| Thermal test current |

5 A |

| Utilisation category AC-15 |

230 VAC |

| Utilisation category DC-13 |

24 VDC |

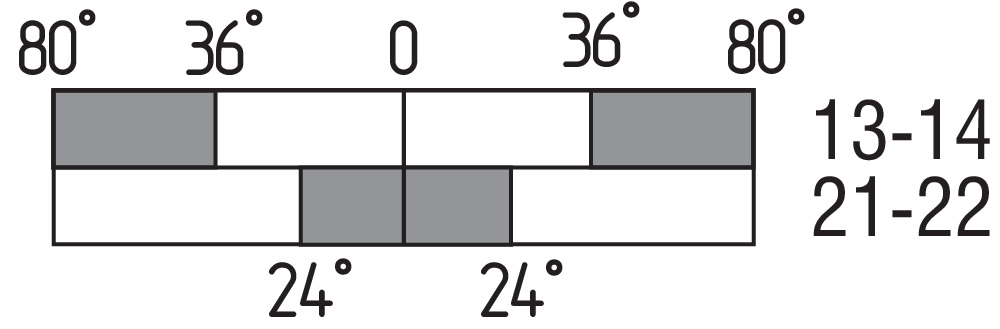

| Switching element |

NO contact, NC contact |

| Switching principle |

Slow action |

| Bounce duration, maximum |

3 ms |

| Maximale Schalthäufigkeit |

1,800 /h |

| Material of the contacts, electrical |

Silver |

Scope of delivery

| Scope of delivery |

Ex-certified screwed cable gland |

Language filter

Datasheet

Operating instructions and Declaration of conformity

ATEX Certificate

IECEx certification

UL Certificate

CCC certification

INMETRO certification

PESO-Zertifikat

SISTEMA-VDMA library

Download the latest version of Adobe Reader

Product picture (catalogue individual photo)

Dimensional drawing basic component

Dimensional drawing basic component

Dimensional drawing actuator

Switch travel diagram

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | EX-T 335 |

| Type: | See ordering code |

| Marking: | D II 2G Ex db eb IIC T6 Gb D II 2D Ex tb IIIC T80°C Db |

| Description of the component: | Positive break position switch for safety functions or position switch without safety function |

| Relevant Directives: | Machinery Directive (for safety components, whose type plate is labelled "Safety component") | 2006/42/EC |

| Explosion Protection Directive (ATEX) | 2014/34/EU | |

| RoHS-Directive | 2011/65/EU |

| Applied standards: | EN 60947-5-1:2017 + AC:2020 EN IEC 60079-0:2018 EN 60079-31:2014 EN IEC 60079-7:2015 + A1:2018 EN 60079-31:2014 |

| Notified body, which approved the full quality assurance system, referred to Appendix IV, 2014/34/EU: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| Notified body for Type Examination: | DEKRA Testing and Certification GmbH Dinnendahlstraße 9 44809 Bochum ID n°: 0158 |

| EU-Type Examination Certificate: | BVS 09 ATEX E 152 |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, September 27, 2023 |

|

| Authorised signature Philip Schmersal Managing Director |

Schmersal Ltd., Sparrowhawk Close, WR14 1GL Malvern

The details and data referred to have been carefully checked. Images may diverge from original. Further technical data can be found in the manual. Technical amendments and errors possible.

Generated on: 12/02/2025, 00:51

.png?id=4b3ac43987d949cdc69fc958aa708ca2)