Safety sensors

EX-RSS16

- Explosion protection for ATEX Zones 2 and 22

- Thermoplastic enclosure

- RFID-technology for needs-based protection against tampering

- 3 different directions of actuation

- Door stop with magnetic latching

- Suitable for series-wiring

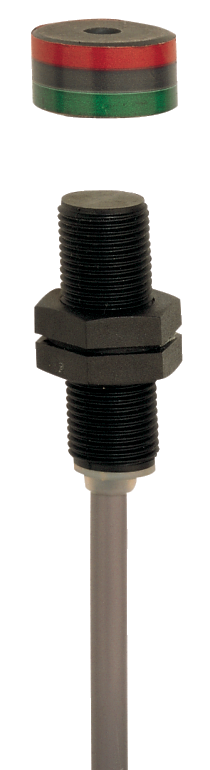

EX-BNS 120

- Explosion protection for ATEX Zones 2 and 22

- Ø M12

- Thermoplastic enclosure

- Particularly large switching distance

- Insensitive to transverse misalignment

- Suitable for food processing industry only in combination with BP 15 SS

- no mechanical wear

EX-BNS 180

- Explosion protection for ATEX Zones 2 and 22

- Thermoplastic enclosure

- Ø M18

- Particularly large switching distance

- Insensitive to transverse misalignment

- Suitable for food processing industry only in combination with BP 15 SS

- no mechanical wear

EX-CSS 180

- Explosion protection for ATEX Zones 2 and 22

- Ø M18

- Thermoplastic enclosure

- Electronic contact-free, coded system

- Misaligned actuation possible

- High repeat accuracy of the switching points

- Max. length of the sensor chain 200 m

- Early warning when operating near the limit of the sensor's hysteris range

- Self-monitoring series-wiring of 16 sensors

- 2 short-circuit proof PNP safety outputs

EX-BNS 303

- Explosion protection for ATEX Zones 2 and 22

- Ø M30

- Thermoplastic enclosure

- With coding

- Insensitive to transverse misalignment

- Suitable for food processing industry only in combination with BPS 303 SS

- no mechanical wear

EX-BNS 33

- Explosion protection for ATEX Zones 2 and 22

- Thermoplastic enclosure

- 88 mm x 25 mm x 13 mm

- Concealed mounting possible

- Insensitive to transverse misalignment

- no mechanical wear

EX-BNS 250

- Explosion protection for ATEX Zones 2 and 22

- Thermoplastic enclosure

- small body

- Concealed mounting possible

- Insensitive to transverse misalignment

- no mechanical wear

- 64 mm x 29.5 mm x 15.5 mm (incl. protective enclosure)

EX-BNS40S

- Explosion protection for ATEX Zones 2 and 22

- Stainless steel enclosure

- 88 mm x 27 mm x 14,5 mm

- Concealed mounting possible

- Insensitive to transverse misalignment

- no mechanical wear

- Suitable for food processing industry

- Cable connection suitable for the food industry

Application:

The magnetic safety sensors are used to monitor the position of sliding, hinged or removable safety guards. Devices without integral evaluation must used only in combination with a guard door monitor up to control category 4 in accordance with ISO 13849-1 for safety tasks in accordance with IEC 60947-5-3.

The use of magnetic safety sensors is of particular advantage in cases where extremely dirty conditions can occur or high hygienic standards need to be maintained. This is provided by the simplicity of cleaning of the devices.

Another advantage is the possibility of concealed mounting behind non-magnetic materials. Working surfaces and storage areas can be arranged without the need for dust-collecting edges or other functionally required cut-outs or projections.

In applications, where a precise approach is not possible and larger tolerances are required, the magnetic safety sensors of the BNS series can also be used.

Design and mode of operation:

These devices comprise a multi-channel magnetic safety sensors and an actuating magnet.

All magnetic safety sensors are in thermoplastic enclosures and protected to protection class IP 67 or 65.

The magnetic safety sensors are used to monitor the position of sliding, hinged or removable safety guards. Devices without integral evaluation must used only in combination with a guard door monitor up to control category 4 in accordance with ISO 13849-1 for safety tasks in accordance with IEC 60947-5-3.

The use of magnetic safety sensors is of particular advantage in cases where extremely dirty conditions can occur or high hygienic standards need to be maintained. This is provided by the simplicity of cleaning of the devices.

Another advantage is the possibility of concealed mounting behind non-magnetic materials. Working surfaces and storage areas can be arranged without the need for dust-collecting edges or other functionally required cut-outs or projections.

In applications, where a precise approach is not possible and larger tolerances are required, the magnetic safety sensors of the BNS series can also be used.

Design and mode of operation:

These devices comprise a multi-channel magnetic safety sensors and an actuating magnet.

All magnetic safety sensors are in thermoplastic enclosures and protected to protection class IP 67 or 65.

.png?id=bb44e9061d048e5250879d3fc4285be0)