Blokady elektromagnetyczne

Poziom kodowania zgodny z EN ISO 14119

Zasada działania

Zasada ryglowania

Siła ryglowania zgodnie z EN ISO 14119

Certyfikaty

Temperatura otoczenia, maksimum

Temperatura otoczenia, minimalne

Ryglowanie napięciem

Ryglowanie sprężyną

Diagnostyka szeregowa

Łączenie szeregowe

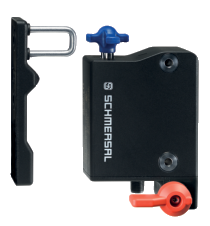

AZM40

- Kompaktowy, cienki design

- 119,5 mm x 40 mm x 20 mm

- duża siła ryglująca 2000 N

- Siła zatrzasku 40 N

- Technologia RFID dla opartej na potrzebach uzytkownika ochrony przed manipulacjami

- Indywidualnie kodowane warianty o wysokim stopniu kodowania wg ISO 14119

- Jedna wersja dla drzwi uchylnych i przesuwnych

- Aktywator może bezstopniowo uruchomić ryglowanie w zakresie 180 stopni

- Symetryczny montaż, śruby po obu stronach

AZM150

- Obudowa z tworzywa termoplastycznego

- 8 płaszczyzn aktywacji dzieki obracanej głowicy

- Łatwy montaż, szczególnie na profilach 40 mm

AZM150I

- Obudowa z tworzywa termoplastycznego

- 8 płaszczyzn aktywacji dzieki obracanej głowicy

- Łatwy montaż, szczególnie na profilach 40 mm

- Indywidualnie kodowane warianty o wysokim stopniu kodowania wg ISO 14119

AZM201

- Obudowa z tworzywa termoplastycznego

- Maks. długość łańcucha czujników 200 m

- Okablowanie szeregowe z diagnostyką

- Kodowanie zgodnie z ISO 14119 za pomocą technologii RFID

- 3 diody LED pokazujące stan pracy

- Technologia czujnikowa pozwala na przesunięcie aktywatora w stosunku do blokady o ± 5 mm w pionie i ± 3 mm w poziomie

- odpowiednie dla osłon uchylnych i przesuwnych

- Inteligentna diagnostyka

- Zwolnienie ręczne

- Klasa ochrony IP66, IP67

- duża siła ryglująca 2000 N

- konstrukcja symetryczna, montaż na profilach 40mm

- Wyjścia bezpieczeństwa OSSD

- Możliwość późniejszego zamontowania odryglowania awaryjnego / odblokowania awaryjnego

AZM300

- higieniczna konstrukcja

- Klasa ochrony IP69

- Odpowiednia dla montażu w systemach profilowych

- Obudowa z tworzywa termoplastycznego

- Technologia RFID dla opartej na potrzebach uzytkownika ochrony przed manipulacjami

- 3 różne kierunki aktywacji

- zwarta budowa

- 3 diody LED pokazujące stan pracy

- odpowiednie dla osłon uchylnych i przesuwnych

- Łączenie szeregowe

- Zwolnienie ręczne

AZM400

- Bistabilny, napędzany elektrycznie sworzeń ryglujący

- Siła ryglująca 10.000 N

- Zwolnienie możliwe przy sile poprzecznej do 300N

- PL e / kat. 4 / SIL 3 dla funkcji ryglowania i kontroli zamknięcia

- Dwukanałowy sygnał wejściowy funkcji zamknięcia osłony

- Współpraca z wyjściami P/P i P/N

- Wysoka tolerancja przesunięcia osłon

MZM 100

- Automatyczne zatrzaśnięcie

- Blokady elektromagnetyczne z nowatorską i unikalną zasadą działania.

- 40 mm x 179 mm x 40 mm

- Bezkontaktowy i kodowany system elektroniczny

- Obudowa z tworzywa termoplastycznego

- Maks. długość łańcucha czujników 200 m

- 3 diody LED pokazujące stan pracy

- Technologia czujnikowa pozwala na przesunięcie aktywatora w stosunku do blokady o ± 5 mm w pionie i ± 3 mm w poziomie

- Inteligentna diagnostyka

- Okablowanie szeregowe z diagnostyką

AZM 161

- Obudowa z tworzywa termoplastycznego

- z podwójną izolacją

- blokada z zabezpieczeniem przed nieprawidłowym zaryglowaniem

- 130 mm x 90 mm x 30 mm

- 6 Zestyki

- długa żywotność

AZM 161I

- kodowanie indywidualne

- Obudowa z tworzywa termoplastycznego

- z podwójną izolacją

- blokada z zabezpieczeniem przed nieprawidłowym zaryglowaniem

- 130 mm x 90 mm x 30 mm

- 6 Zestyki

- długa żywotność

AZM 170

- Obudowa z tworzywa termoplastycznego

- z podwójną izolacją

- zwarta budowa

- 90 mm x 84 mm x 30 mm

- blokada z zabezpieczeniem przed nieprawidłowym zaryglowaniem

- długa żywotność

- duża siła ryglująca

AZM 170I

- kodowanie indywidualne

- Obudowa z tworzywa termoplastycznego

- z podwójną izolacją

- zwarta budowa

- 90 mm x 84 mm x 30 mm

- blokada z zabezpieczeniem przed nieprawidłowym zaryglowaniem

- długa żywotność

- duża siła ryglująca

AZM190

- Obudowa z tworzywa termoplastycznego

- długa żywotność

- blokada z zabezpieczeniem przed nieprawidłowym zaryglowaniem

- 89 mm x 178 mm x 41 mm

- Możliwy obrót głowicy o 4 x 90°

- 2 wloty kablowe M 20 x 1.5

- Przedział okablowania

- wąska obudowa, nadaje się zwłaszcza do mocowania na drzwiach uchylnych, profilach aluminiowych i ogrodzeniach

- Mechanizm uszczelniający zapobiegający gromadzeniu się brudu

- Zacisk śrubowy

AZM 415

- Obudowa metalowa

- blokada z zabezpieczeniem przed nieprawidłowym zaryglowaniem

- Wytrzymała budowa

- długa żywotność

- 2 wloty kablowe M 20 x 1.5

- Zacisk śrubowy

ELEKTROMAGNETYCZNE BLOKADY BEZPIECZEŃSTWA AZM I MZM

Elektromagnetyczna blokada bezpieczeństwa z serii AZM lub MZM gwarantuje, że obrotowe, przesuwne i zdejmowane osłony, takie jak kołpaki, kratki lub drzwi, można otworzyć tylko wtedy, gdy nie występują niebezpieczne sytuacje. Obejmuje to np. ruchy bezwładnościowe łańcuchów, walców lub wałów. Blokady współpracują z przekaźnikowymi modułami bezpieczeństwa oraz z bezpiecznymi modułami kontroli bezruchu i członami czasowymi. Poza zagwarantowaniem bezpieczeństwa pracy elektromagnetyczna blokada bezpieczeństwa jest stosowana również tam, gdzie otwarcie urządzenia ochronnego nie jest pożądane. W zakresie ochrony procesu może to oznaczać niedopuszczalną lub niepożądaną ingerencję w proces produkcyjny.ELEKTROMAGNETYCZNA BLOKADA BEZPIECZEŃSTWA: BUDOWA I ZASADA DZIAŁANIA

W przypadku każdej elektromagnetycznej blokady bezpieczeństwa grupa Schmersal opiera się na koncepcji „oddzielnego aktywatora”. Zostanie to zilustrowane na przykładzie drzwi ochronnych: Element aktywujący elektromagnetyczną blokadę bezpieczeństwa jest zamocowany do drzwi, tzn. do ruchomej części urządzenia ochronnego. Natomiast blokada jest zamontowana na stałe do słupka drzwi ochronnych. Gdy drzwi zostaną zamknięte, element obsługi „znika” wraz z nimi; elektromagnetyczna blokada bezpieczeństwa blokuje drzwi ochronne za pomocą sworznia. Maszynę można uruchomić dopiero w tym stanie. Położenie sworznia blokującego jest stale monitorowane. W stanie odblokowanym po otwarciu urządzenia ochronnego aktywator zostanie oddzielony od urządzenia podstawowego. Powoduje to automatyczne otwarcie zestyków NC i zamknięcie zestyków NO.

RÓŻNE AKCESORIA DO ELEKTROMAGNETYCZNYCH BLOKAD BEZPIECZEŃSTWA

Elektromagnetyczne blokady bezpieczeństwa od dziesięcioleci należą do podstawowego programu grupy Schmersal. Oferta serii i konstrukcji jest więc odpowiednio szeroka. Ponadto są dostępne różne aktywatory i akcesoria. Obejmują one urządzenia centrujące do wstępnego pozycjonowania, złącza wtykowe i śruby zabezpieczające. Dostępne są również modele z certyfikatem ATEX oraz wersje z wbudowanym interfejsem „AS-Interface Safety at Work”. Szczegółowe informacje dotyczące akcesoriów i poszczególnych elektromagnetycznych blokad bezpieczeństwa znajdują się w katalogu online firmy Schmersal.

.png?id=d0ac8913a0bfcc62dbb2d1f75aa8fbce)