Solenoid interlocks

Coding level according to EN ISO 14119

Working principle

Interlocking principle

Holding force FZh in accordance with EN ISO 14119

Certificates

Ambient temperature, maximum

Ambient temperature, minimum

Power to lock

Power to unlock

Serial diagnostics

Series-wiring

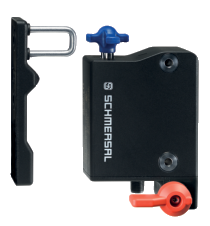

AZM40

- Compact, flat design

- 119,5 mm x 40 mm x 20 mm

- High holding force 2000

- Latching force 40 N

- RFID-technology for needs-based protection against tampering

- Individually coded version with coding level "High" according to ISO 14119

- Only one version for hinged and sliding doors

- Actuator can approach interlock continuously within a 180 degree angle.

- Symmetrical mounting, can be bolted on either side

AZM150

- Thermoplastic enclosure

- Eight approach levels thanks to rotating head

- Simple fitting, especially on 40 mm profiles

AZM150I

- Thermoplastic enclosure

- Eight approach levels thanks to rotating head

- Simple fitting, especially on 40 mm profiles

- Individually coded version with coding level "High" according to ISO 14119

AZM201

- Thermoplastic enclosure

- Max. length of the sensor chain 200 m

- Self-monitoring series-wiring

- Coding in accordance to ISO 14119 by using RFID-Technology

- 3 LEDs to show operating conditions

- Sensor technology permits an offset between actuator and interlock of ± 5 mm vertically and ± 3 mm horizontally

- Suitable for hinged and sliding guards

- Intelligent diagnosis

- Manual release

- Protection class IP66, IP67

- High holding force 2000

- symmetrical construction form, assembly on 40mm profiles

- OSSD safety outputs

- Emergency exit / Emergency release suitable for retrofitting

AZM300

- hygienic design

- Protection class IP 69

- Suitable for mounting to profile systems

- Thermoplastic enclosure

- RFID-technology for needs-based protection against tampering

- 3 different directions of actuation

- Compact design

- 3 LEDs to show operating conditions

- Suitable for hinged and sliding guards

- Series-wiring

- Manual release

AZM400

- Bistable, motor-driven system

- Clamping force 10.000

- Release possible against lateral forces up to 300 N

- PL e / cat. 4 / SIL 3 for interlocking and guard locking function

- Two-channel input signal of the guard locking function

- Operation on P/P- and P/N-switching outputs

- High tolerance to door misalignment

MZM 100

- Automatic latching

- Solenoid interlocks with innovating and unique operating principle

- 40 mm x 179 mm x 40 mm

- Electronic contact-free, coded system

- Thermoplastic enclosure

- Max. length of the sensor chain 200 m

- 3 LEDs to show operating conditions

- Sensor technology permits an offset between actuator and interlock of ± 5 mm vertically and ± 3 mm horizontally

- Intelligent diagnosis

- Self-monitoring series-wiring

AZM 161

- Thermoplastic enclosure

- Double-insulated

- Interlock with protection against incorrect locking.

- 130 mm x 90 mm x 30 mm

- 6 Contacts

- Long life

AZM 161I

- Individual coding

- Thermoplastic enclosure

- Double-insulated

- Interlock with protection against incorrect locking.

- 130 mm x 90 mm x 30 mm

- 6 Contacts

- Long life

AZM 170

- Thermoplastic enclosure

- Double-insulated

- Compact design

- 90 mm x 84 mm x 30 mm

- Interlock with protection against incorrect locking.

- Long life

- High holding force

AZM 170I

- Individual coding

- Thermoplastic enclosure

- Double-insulated

- Compact design

- 90 mm x 84 mm x 30 mm

- Interlock with protection against incorrect locking.

- Long life

- High holding force

AZM190

- Thermoplastic enclosure

- Long life

- Interlock with protection against incorrect locking.

- 89 mm x 178 mm x 41 mm

- Actuating head can be repositioned by 4 x 90°

- 2 cable entries M 20 x 1.5

- Wiring compartment

- Slim design, particularly suitable for fitting on hinged doors, aluminium profiles and fencing

- Sealing mechanism to prevent the ingress of dirt

- Cut clamp termination

AZM 415

- Metal enclosure

- Interlock with protection against incorrect locking.

- Robust design

- Long life

- 2 cable entries M 20 x 1.5

- Cut clamp termination

SAFETY INTERLOCKS AZM AND MZM

A safety interlock from the AZM or MZM series prevents rotary, lateral and removable guards, such as covers, grids and doors, from being opened until hazardous states have been eliminated. These include, for example, overrunning movements of chains, rollers or shafts. The guard locking devices work together with safety relay modules and safe standstill monitors or timers. Outside of occupational safety, a solenoid interlock is also used where the opening of a safety guard is not desired. In the area of process protection, this can mean unauthorised or undesirable interference in the production process.SOLENOID INTERLOCK: STRUCTURE AND MODE OF ACTION

The Schmersal Group relies on the concept of the ‘separate actuator’ for every safety interlock. This will be illustrated using the example of a safety door: The actuating element of the solenoid interlock is attached to the door itself - i.e. to the moving part of the guard. The guard locking, on the other hand, is permanently mounted on the post of the safety door. If the door is now closed, the operating element ‘disappears’ with it; the solenoid interlock blocks the safety door with a bolt. The machine can only be started in this state. The position of the locking bolt is constantly monitored. When unlocked, the actuator is disconnected from the basic device when the safety guard is opened. This automatically opens the normally closed contacts and closes the normally open contacts.

VARIOUS ACCESSORIES FOR SOLENOID INTERLOCKS

Solenoid interlocks have been part of the Schmersal Group's core programme for decades. The range of series and designs is correspondingly extensive. Various actuators and accessories are also available. These include door catches for pre-positioning, plug-in connections and safety screws. Models with ATEX certification and versions with integrated AS Interface Safety at Work are also available. Detailed information on accessories and each individual solenoid interlock can be found in the Schmersal online catalogue.

.png?id=bb44e9061d048e5250879d3fc4285be0)