AZ201ST2-T-1P2P

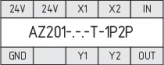

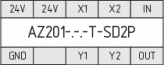

| 製品タイプの説明: AZ201-(1)-(2)-T-(3) |

| なし | 標準コード化 |

| I1 | 個別コード化 |

| I2 | 個別コード化 複数のティーチング |

| (2) | |

| SK | ネジ接続 |

| CC | ケージクランプ式 |

| (3) | |

| 1P2P | 1 PNPタイプ診断出力及び2 PNPタイプ安全出力 |

| SD2P | シリアル診断出力及び2 PNP安全出力 |

- 熱可塑性樹脂性ケース

- 要求に基づいた無効化防止のためのRFID技術

- センサチェーンの最大長さ200m

- 自己診断機能付の31個のセンサ直列接続

- 動作状態表示用3個のLED

- センサ技術によりアクチュエータとスイッチは垂直方向± 5 mm、水平方向± 3 mmのズレが可能

- ヒンジ・スライド式扉用

- インテリジェント診断機能

注文データ

| 製品タイプの説明 |

AZ201ST2-T-1P2P |

| 部品番号(注文番号) |

103015816 |

| EAN(欧州部品番号) |

4030661504308 |

| eCl@ss番号、バージョン12.0 |

27-27-26-02 |

| eCl@ss番号、バージョン11.0 |

27-27-26-02 |

| eCl@ss番号、バージョン9.0 |

27-27-26-02 |

| ETIM番号、バージョン7.0 |

EC002592 |

| ETIM番号、バージョン6.0 |

EC002592 |

認証

|

TÜV cULus FCC IC UKCA ANATEL |

一般データ

| 規格 |

EN ISO 13849-1 EN ISO 14119 EN IEC 60947-5-3 EN IEC 61508 |

| 一般情報 |

ユニバーサルコード化 |

| EN ISO 14119に準拠したコーディングレベル |

Low |

| アクティブ原理 |

RFID, 125 kHz |

| 送信機出力 RFID、最大 |

-6 dBm |

| ハウジング 材質 |

グラスファイバー強化熱可塑性樹脂 |

| リスク持続時間、最大 |

200 ms |

| アクチュエーターの応答時間、最大 |

100 ms |

| 入力の応答時間、最大 |

0.5 ms |

| 総重量 |

410 g |

一般データ - 仕様

| 短絡検出 |

Yes |

| 短絡監視 |

Yes |

| 直列接続 |

Yes |

| 安全機能 |

Yes |

| 一体型システム診断、状態 |

Yes |

| 安全接点数 |

2 |

安全性評価

| 規定 |

EN ISO 13849-1 EN IEC 61508 |

| パフォーマンスレベル、最大 |

e |

| カテゴリー |

4 |

| PFH値 |

1.90 x 10⁻⁹ /h |

| PFD値 |

1.60 x 10⁻⁴ |

| 安全インテグリティレベル (SIL), 安全度水準に適合 |

3 |

| ミッションタイム |

20 年 |

機械的データ

| 機械的寿命、最小 |

1,000,000 操作 |

| ラッチ力 |

30 N |

| 作動速度, 最大 |

0.2 m/s |

| 固定ネジの種類 |

2x M6 |

| ハウジングカバー用固定ネジの締め付けトルク、最小 |

0.7 Nm |

| ハウジングカバー用固定ネジの締め付けトルク、最大 |

1 Nm |

| 注記 |

Torx T10 |

Mechanical data - Switching distances

| 安定動作距離 "ON" Sao |

4 mm |

| 安定動作距離 "OFF" Sar |

30 mm |

| 注記 (動作距離) |

All switching distances in accordance EN IEC 60947-5-3 |

| ヒステリシス (切替距離), 最大 |

1.5 mm |

| 切換位置再現性 R |

0.5 mm |

機械的データ - 電気機械式

| センサーチェーンの長さ、最大 |

200 m |

| 注意(センサーチェーンの長) |

ケーブル長とケーブル径により、出力電流による電圧降下が変化します。 |

| 注意 (直列接続) |

無制限のデバイス数,外部ラインヒューズオーバーサーブ、シリアル診断SDの場合、最大31デバイス。 |

| 接続 |

M12コネクター, 8芯 |

機械的データ - 寸法

| センサー長 |

50 mm |

| センサーの幅 |

40 mm |

| センサーの高さ |

220 mm |

環境条件

| 保護等級 |

IP66 IP67 |

| 使用周囲温度 |

-25 ... +70 °C |

| 保管および輸送温度 |

-25 ... +85 °C |

| 相対湿度, 最大 |

93 % |

| 注記 (相対湿度) |

non-condensing non-icing |

| 耐振動 |

10 ~ 150 Hz、振幅 0.35 mm |

| 耐衝撃 |

30 g / 11 ms |

| 保護等級 |

III |

| 許容される設置高度/標高(海抜), 最大 |

2,000 m |

環境条件 - 絶縁値

| 定格絶縁電圧 Ui |

32 VDC |

| 定格インパルス耐電圧 Uimp |

0.8 kV |

| 過電圧カテゴリー |

III |

| 汚染度 |

3 |

電気的データ

| 動作電圧 |

24 VDC -15 % / +10 % |

| 無負荷供給電流 I0, 典型的 |

50 mA |

| 定格動作電圧 |

24 VDC |

| 動作電流 |

700 mA |

| 要求定格短絡電流 |

100 A |

| 外部ワイヤとデバイスのヒューズ定格 |

2 A gG |

| 準備時間、最大 |

4,000 ms |

| 開閉頻度、最大 |

1 Hz |

Electrical data - Safety digital inputs

| 指定、安全入力 |

X1 and X2 |

| スイッチングのしきい値 |

−3 V … 5 V (Low) 15 V … 30 V (High) |

| 24Vの時の消費電流 |

5 mA |

| テストパルス幅、最大 |

1 ms |

| テストパルス間隔、最小 |

100 ms |

| 分類 ZVEI CB24I、シンク |

C1 |

| 分類 ZVEI CB24I、ソース |

C1 C2 C3 |

Electrical data - Safety digital outputs

| 指定、安全出力 |

Y1 and Y2 |

| 定格動作電流(安全出力) |

250 mA |

| 制御エレメントのデザイン |

short-circuit proof, p-type |

| 電圧降下 Ud、最大 |

4 V |

| 残留電流 lr, 最大 |

0.5 mA |

| 電圧, 使用カテゴリー DC-13 |

24 VDC |

| 電流、使用カテゴリーDC-13 |

0.25 A |

| テストパルス間隔、標準 |

1000 ms |

| テストパルス幅、最大 |

0.5 ms |

| 分類 ZVEI CB24I、ソース |

C2 |

| 分類 ZVEI CB24I、シンク |

C1 C2 |

電気的データ - 診断出力

| 指定、診断出力 |

OUT |

| 動作電流 |

50 mA |

| 制御エレメントのデザイン |

short-circuit proof, p-type |

| 電圧降下 Ud、最大 |

4 V |

| 電圧, 使用カテゴリー DC-13 |

24 VDC |

| 電流、使用カテゴリーDC-13 |

0.05 A |

状態表示

| 注記 (LED切り替え状態表示) |

Operating condition: LED green Error / functional defect: LED red Supply voltage UB: LED green |

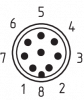

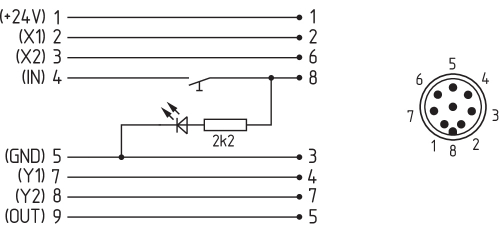

ピン配列

| ピン 1 |

A1 Supply voltage UB |

| ピン 2 |

X1 Safety input 1 |

| ピン 3 |

A2 GND |

| ピン 4 |

Y1 Safety output 1 |

| ピン 5 |

OUT Diagnostic output |

| ピン 6 |

X2 Safety input 2 |

| ピン 7 |

Y2 Safety output 2 |

| ピン 8 |

n.c. |

納入品目

| 納入時同梱 |

Actuator must be ordered separately. |

アクセサリー

| 推奨(アクチュエーター) |

AZ/AZM201-B1 AZ/AZM201-B30 |

言語フィルター

データシート

Operating instructions and Declaration of conformity

EC Declaration of conformity

TÜV certification

UL Certificate

IC-Zertifikat

ANATEL certification

SISTEMA-VDMA library

Adobe Readerの最新版をダウンロードしてください

Product picture (catalogue individual photo)

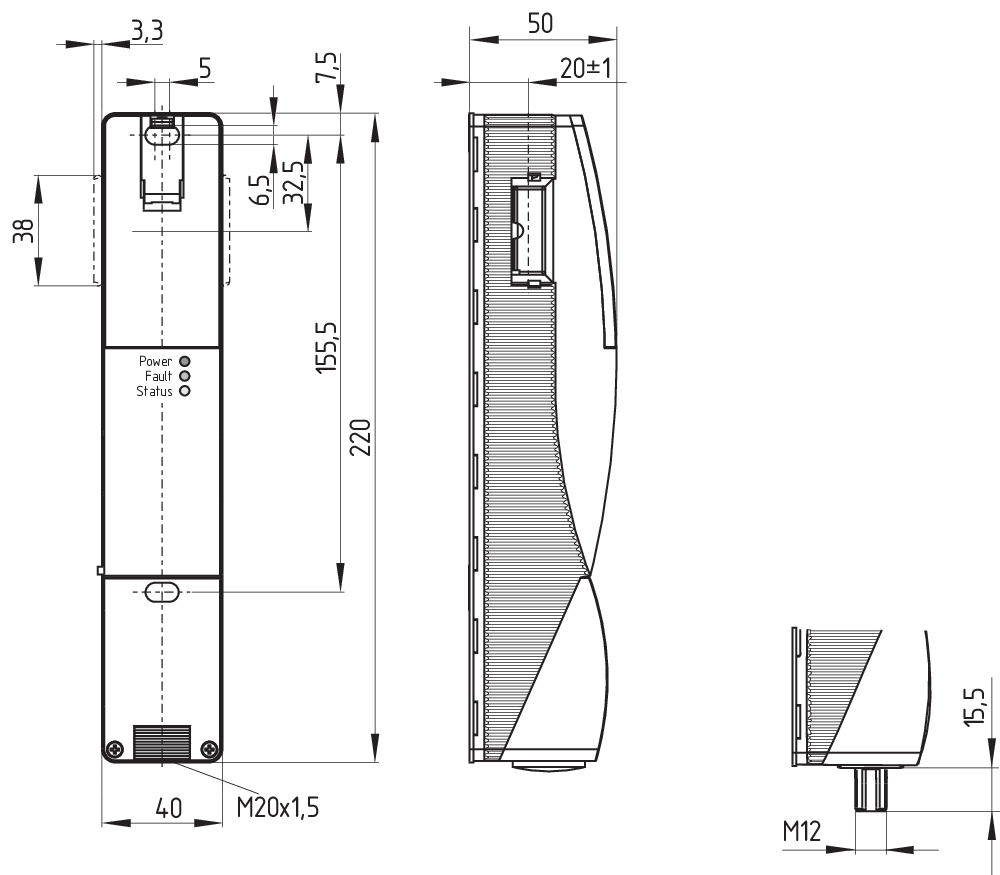

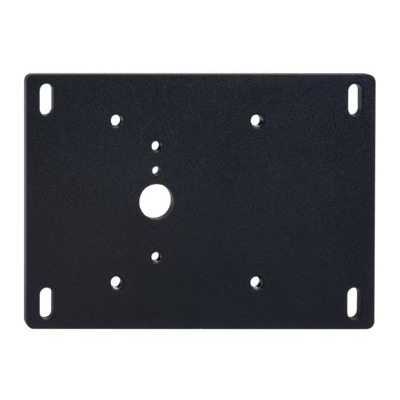

Dimensional drawing basic component

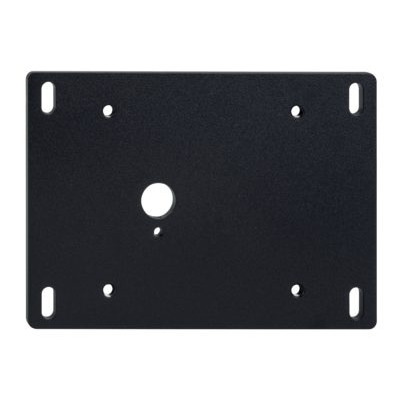

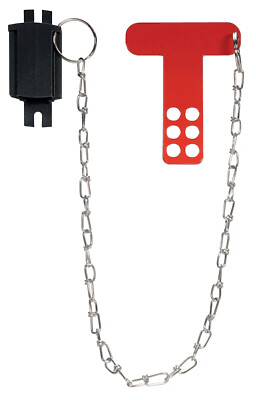

Assembly example

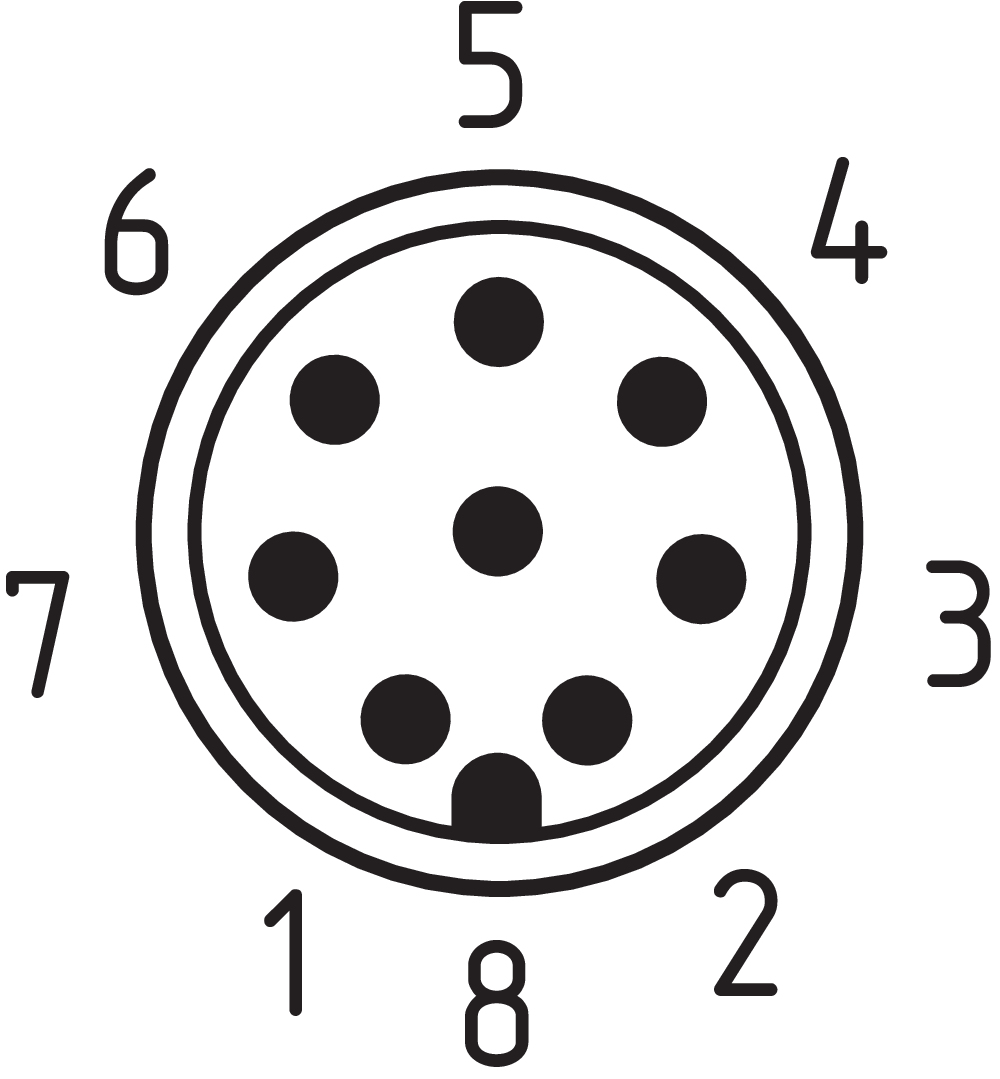

Contact arrangement

Table of Contents

- 1 この文書について

- 1.1 機能

- 1.2 取扱説明書の対象グループ: 認定された有資格者

- 1.3 使用記号の説明

- 1.4 適切な使用

- 1.5 安全上のご注意

- 1.6 誤使用に関する警告

- 1.7 免責事項

- 2 製品内容

- 2.1 型番

- 2.2 特殊仕様

- 2.3 目的

- 2.4 技術データ

- 3 取り付け

- 3.1 通常の取り付け方法

- 3.2 外形図

- 4 電気配線

- 4.1 電気配線上のご注意

- 4.3 接続する安全制御機器の要求事項

- 4.4 シリアル診断 -SD

- 4.6 直列配線の配線例

- 5 アクチュエータのティーチング / アクチュエータ検出

- 6 動作原理と診断機能

- 6.1 バージョン毎の安全出力の動作

- 6.2 診断用LED

- 6.3 診断出力・電磁ロック付きインターロック

- 6.4 シリアル診断機能SD付きセーフティスイッチ

- 7 立ち上げと保全

- 8 取り外し・廃棄

- 8.1 取り外し

- 8.2 廃棄処分

- 9 付録 – 特殊仕様

1 この文書について

1.1 機能

本書は、本製品の安全な操作と解体のために、取付け、セットアップ、試運転に必要なすべての情報を提供します。装置に同封されている取扱説明書は、読み易い状態で、完全版を機器の付近に保管してください。

1.2 取扱説明書の対象グループ: 認定された有資格者

この取扱説明書に記述された全ての操作は、使用者によって認められた専門技術者が行ってください。

この取扱説明書を熟読し、コンポーネントの据付及び運転の前に、労働安全及び事故予防のための適用可能な全規定に付いてご確認ください。

組み立て作業員は、コンポーネントの選定、取り付け、内蔵に対して、他の技術仕様を遵守するのと同じように、慎重に整合規格を選択しなければなりません

1.3 使用記号の説明

- 情報、助言、注釈:この表示は役立つ追加情報を示します。

- 注意: 取り扱いを誤った場合に、故障、機能不良が想定される内容を示しています。

警告:取り扱いを誤った場合に、傷害を負う可能性が想定される内容、及び物的損害の発生が想定される内容を示しています。

1.4 適切な使用

シュメアザールが提供する製品は、個人消費者向けではありません。

本製品は、設備や機械の一部として安全関連機能を果たすために開発されたものです。設備や機械全体が適格に動作する事を保証する事は、製造者の責任です。

セーフティスイッチは下記に挙げられたバージョン、又は製造者によって許可されたアプリケーションに対してのみ使用しなければなりません。アプリケーションの範囲に関する詳細は、「製品内容」の項を参照ください。

1.5 安全上のご注意

ユーザーはこの取扱説明書に記載されている、安全上の説明、各国の設置基準、並びに全ての周知の安全規則や事故防止規則を遵守しなければなりません。

- 詳細な技術情報に付いてはシュメアザールカタログ、又はインターネット(products.schmersal.com)上のオンラインカタログをご参照下さい。

仕様などの記載内容について予告なく変更する事があります。あらかじめご了承ください

取付、据付、操作及び保全に関する説明書と同様に安全に関する注意が遵守されていれば、残留リスクはありません。

1.6 誤使用に関する警告

- 本製品に対する不適切な使い方や、無効化により、人への危険や機械設備への損傷を招く事があります。

1.7 免責事項

誤った取り付けやこの取扱説明書を正しく理解していないために起こった損害、故障は、Schmersalの免責事項となります。また、製造者に許可されていない代替・付属品による損害は、製造者の免責事項となります。

安全上の理由から、デバイスに対する独自の変更や不適切な修理、部品の交換や改造は厳として認められず、それが理由で発生した故障や事故に対し、シュメアザールは責任を一切負いません。

2 製品内容

2.1 型番

| 製品タイプの説明: AZ201-(1)-(2)-T-(3) |

| なし | 標準コード化 |

| I1 | 個別コード化 |

| I2 | 個別コード化 複数のティーチング |

| (2) | |

| SK | ネジ接続 |

| CC | ケージクランプ式 |

| (3) | |

| 1P2P | 1 PNPタイプ診断出力及び2 PNPタイプ安全出力 |

| SD2P | シリアル診断出力及び2 PNP安全出力 |

| アクチュエータ | 以下に適します |

|---|---|

| AZ/AZM201-B1-... | スライド式ガード |

| AZ/AZM201-B30-... | ヒンジ式ガード |

| AZ/AZM201-B40-... | 折り重ね式ヒンジドア |

- この取扱説明書に記載されている説明通りに正しく行われている場合に限り、安全機能は、従って機械指令への適合は維持されます。

2.2 特殊仕様

型式記号で挙げられていない特別仕様は一般使用に準じます。

- 特別な情報、または特別バージョンに関する標準から逸脱した情報は、最後の章「付録 – 特別バージョン」に記載されています。

2.3 目的

非接触式セーフティスイッチは、安全回路での用途向けに設計されており、可動ガードの位置やロック状態の監視に使用されます。

セーフティスイッチは、ISO 14119に基づきタイプ4のインターロック機器に分類されます。個別コード化の仕様ではコード化レベルHighに分類されます。

安全機能により、ガードが開いていると安全出力はOFFとなり、ガードが開いている間はOFFの状態を維持します。

直列接続ができます。直列接続の場合、リスク時間は変わらず、反応時間は、技術データで指定された追加ユニットごとの入力の反応時間の合計だけ増加します。コンポーネントの数は、技術データに基づく外部ケーブルヒューズ保護と、ケーブル損失によってのみ制限されます。シリアル診断を備えた最大 31 のデバイス バリアントを直列に配線できます。

- 使用者は、関連規格と要求される安全レベルに基づいてセーフティチェーンを評価し、設計しなければなりません。複数のセーフティセンサーがある場合、装置個々のPFH値は加算されなければなりません。

- セーフティコンポーネントが組み込まれた制御システムの全体的な構想は、関連規格に対して妥当性を確認しなければなりません。

2.4 技術データ

認証

|

TÜV cULus FCC IC UKCA ANATEL |

一般データ

| 規格 |

EN ISO 13849-1 EN ISO 14119 EN IEC 60947-5-3 EN IEC 61508 |

| 一般情報 |

ユニバーサルコード化 |

| EN ISO 14119に準拠したコーディングレベル |

Low |

| アクティブ原理 |

RFID, 125 kHz |

| 送信機出力 RFID、最大 |

-6 dBm |

| ハウジング 材質 |

グラスファイバー強化熱可塑性樹脂 |

| リスク持続時間、最大 |

200 ms |

| アクチュエーターの応答時間、最大 |

100 ms |

| 入力の応答時間、最大 |

0.5 ms |

| 総重量 |

410 g |

一般データ - 仕様

| 短絡検出 |

Yes |

| 短絡監視 |

Yes |

| 直列接続 |

Yes |

| 安全機能 |

Yes |

| 一体型システム診断、状態 |

Yes |

| 安全接点数 |

2 |

安全性評価

| 規定 |

EN ISO 13849-1 EN IEC 61508 |

| パフォーマンスレベル、最大 |

e |

| カテゴリー |

4 |

| PFH値 |

1.90 x 10⁻⁹ /h |

| PFD値 |

1.60 x 10⁻⁴ |

| 安全インテグリティレベル (SIL), 安全度水準に適合 |

3 |

| ミッションタイム |

20 年 |

機械的データ

| 機械的寿命、最小 |

1,000,000 操作 |

| ラッチ力 |

30 N |

| 作動速度, 最大 |

0.2 m/s |

| 固定ネジの種類 |

2x M6 |

| ハウジングカバー用固定ネジの締め付けトルク、最小 |

0.7 Nm |

| ハウジングカバー用固定ネジの締め付けトルク、最大 |

1 Nm |

| 注記 |

Torx T10 |

Mechanical data - Switching distances

| 安定動作距離 "ON" Sao |

4 mm |

| 安定動作距離 "OFF" Sar |

30 mm |

| 注記 (動作距離) |

All switching distances in accordance EN IEC 60947-5-3 |

| ヒステリシス (切替距離), 最大 |

1.5 mm |

| 切換位置再現性 R |

0.5 mm |

機械的データ - 電気機械式

| センサーチェーンの長さ、最大 |

200 m |

| 注意(センサーチェーンの長) |

ケーブル長とケーブル径により、出力電流による電圧降下が変化します。 |

| 注意 (直列接続) |

無制限のデバイス数,外部ラインヒューズオーバーサーブ、シリアル診断SDの場合、最大31デバイス。 |

| 接続 |

M12コネクター, 8芯 |

機械的データ - 寸法

| センサー長 |

50 mm |

| センサーの幅 |

40 mm |

| センサーの高さ |

220 mm |

環境条件

| 保護等級 |

IP66 IP67 |

| 使用周囲温度 |

-25 ... +70 °C |

| 保管および輸送温度 |

-25 ... +85 °C |

| 相対湿度, 最大 |

93 % |

| 注記 (相対湿度) |

non-condensing non-icing |

| 耐振動 |

10 ~ 150 Hz、振幅 0.35 mm |

| 耐衝撃 |

30 g / 11 ms |

| 保護等級 |

III |

| 許容される設置高度/標高(海抜), 最大 |

2,000 m |

環境条件 - 絶縁値

| 定格絶縁電圧 Ui |

32 VDC |

| 定格インパルス耐電圧 Uimp |

0.8 kV |

| 過電圧カテゴリー |

III |

| 汚染度 |

3 |

電気的データ

| 動作電圧 |

24 VDC -15 % / +10 % |

| 無負荷供給電流 I0, 典型的 |

50 mA |

| 定格動作電圧 |

24 VDC |

| 動作電流 |

700 mA |

| 要求定格短絡電流 |

100 A |

| 外部ワイヤとデバイスのヒューズ定格 |

2 A gG |

| 準備時間、最大 |

4,000 ms |

| 開閉頻度、最大 |

1 Hz |

Electrical data - Safety digital inputs

| 指定、安全入力 |

X1 and X2 |

| スイッチングのしきい値 |

−3 V … 5 V (Low) 15 V … 30 V (High) |

| 24Vの時の消費電流 |

5 mA |

| テストパルス幅、最大 |

1 ms |

| テストパルス間隔、最小 |

100 ms |

| 分類 ZVEI CB24I、シンク |

C1 |

| 分類 ZVEI CB24I、ソース |

C1 C2 C3 |

Electrical data - Safety digital outputs

| 指定、安全出力 |

Y1 and Y2 |

| 定格動作電流(安全出力) |

250 mA |

| 制御エレメントのデザイン |

short-circuit proof, p-type |

| 電圧降下 Ud、最大 |

4 V |

| 残留電流 lr, 最大 |

0.5 mA |

| 電圧, 使用カテゴリー DC-13 |

24 VDC |

| 電流、使用カテゴリーDC-13 |

0.25 A |

| テストパルス間隔、標準 |

1000 ms |

| テストパルス幅、最大 |

0.5 ms |

| 分類 ZVEI CB24I、ソース |

C2 |

| 分類 ZVEI CB24I、シンク |

C1 C2 |

電気的データ - 診断出力

| 指定、診断出力 |

OUT |

| 動作電流 |

50 mA |

| 制御エレメントのデザイン |

short-circuit proof, p-type |

| 電圧降下 Ud、最大 |

4 V |

| 電圧, 使用カテゴリー DC-13 |

24 VDC |

| 電流、使用カテゴリーDC-13 |

0.05 A |

状態表示

| 注記 (LED切り替え状態表示) |

Operating condition: LED green Error / functional defect: LED red Supply voltage UB: LED green |

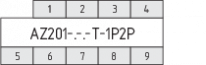

ピン配列

| ピン 1 |

A1 Supply voltage UB |

| ピン 2 |

X1 Safety input 1 |

| ピン 3 |

A2 GND |

| ピン 4 |

Y1 Safety output 1 |

| ピン 5 |

OUT Diagnostic output |

| ピン 6 |

X2 Safety input 2 |

| ピン 7 |

Y2 Safety output 2 |

| ピン 8 |

n.c. |

UL 規格

絶縁電源のみを使用してください。NFPA 79 アプリケーションでのみ使用します。フィールド配線の手段を提供するアダプターは、メーカーから入手出来ます。メーカーの情報をご参照ください。

FCC/IC - 注意

このデバイスは、FCC規則のパート15に準拠しており、またカナダのイノベーション科学経済開発省のライセンス免除RSSに準拠するライセンス免除送信機/受信機が含まれています。

操作は、次の2つの条件の下で許可されます:

(1) 本装置は有害な干渉信号を発生させてはならない。

(2)本装置は干渉信号を許容できなければならない。これらの条件には、本装置が不適切に機能する原因となる干渉信号も含まれます。

本装置は、100mm以上の距離で使用される場合、神経刺激制限(ISED SPR-002)に準拠します。K.A.が明示的に承認していない変更または修正。デバイスを使用するユーザの権限を無効にする可能性があります。

この機器に含まれる免許不要の送受信機は、免許不要の無線機器に適用されるカナダ革新 科学 経済開発(ISED)当局の「無線規格仕様」の要件を満たしています。この機器に含まれる免許不要の送受信機は、免許不要の無線機器に適用されるカナダ革新 科学 経済開発(ISED)当局の「無線規格仕様」の要件を満たしています。以下の2つの条件下で動作が許可されます:

(1) 妨害電波を発生させてはならない。

(2) 本装置は、その機能を損なう可能性がある場合であっても、受信した無線周波数の干渉を許容しなければならない。

本装置は、100mm以上の距離で使用する場合、神経刺激制限(ISED CNR-102)に適合します。

Schmersal GmbH & Co. KG が明示的に承認していない変更または改造を行った場合、 ユーザーによるデバイスの使用許可は無効になる場合があります。

20941-22-14519 | Este equipamento nao tem direito àprotecao contra interferência prejudicial e nao pode causar interferencia em sistemas devidamente autorizados. Para maiores informacores consultar: www.gov.br/anatel |

3 取り付け

3.1 通常の取り付け方法

- 規格ISO 12100、ISO 14119及びISO 14120の関連要求事項を遵守してください。

電磁ロック付きインターロックを取り付けるために、ワッシャ付き M6 ネジ用の取り付け穴が2ヶ所あります(ワッシャー2個のみ同梱)。電磁ロック付きインターロックはドアストッパとして使ってはなりません。取り付け方向は自由です。アクチュエータ挿入部にゴミやホコリが入るような取り付け方向は避けてください。使わないアクチュエータ挿入部は、防塵カバー(製品に同梱)で塞いでください。

2つの電磁ロック付きインターロックの間と、

同じ周波数(125kHz)のその他のシステムとの間の最小距離: 100 mm

アクチュエータの取り付け

適合するアクチュエータの取扱説明書をご参照下さい。

- アクチュエータはガードに確実に取り付け、適切な方法(無効化防止ネジ、接着、ネジヘッドをつぶすなど)により取り外しが出来ないようにしなければなりません。

3.2 外形図

全ての寸法表記はmm

レジェンド

B: アクティブRFIDエリア

- 電磁ロック付きインターロックとアクチュエータの横方向RFID領域の金属部品と磁界は、スイッチング距離に影響を与えたり、誤動作を引き起こしたりする可能性があります。

4 電気配線

4.1 電気配線上のご注意

- 電気配線は専門技術者が非通電の状態で行って下さい。

電源には永続的な過電圧に対する保護が必要です。EN 60204-1に基づく電源ユニットを推奨します。

必要なケーブルのヒューズ保護を設置時に統合する必要があります。

安全出力は制御システムの安全回路に接続出来ます。

- 24V用 X1, X2 のブリッジは-1P2P 及び …-SD2Pでは出荷時にセットされています。

ケーブル引込口には M20 のケーブルグランドを使用します。このケーブルグランドは、使用するケーブルに合わせてユーザーが寸法決めをしなければなりません。ストレイン リリーフと適切な IP 保護等級を備えたケーブル グランドを使用する必要があります。

導体長さxの設定:

- ネジ端子の場合 (SK): 8 mm

- タイプs、rまたはfのケージクランプ(CC)の場合: 7.5 mm

4.3 接続する安全制御機器の要求事項

2チャンネル安全入力、2つのPNPタイプ半導体出力に適します (OSSD)

- セーフティコントローラの構成

安全開閉装置が電子安全監視モジュールに接続されている場合は、少なくとも 100 ミリ秒の不一致時間を設定することをお勧めします。 安全監視モジュールの安全入力は、約1秒のテスト インパルスをブランキングできなければなりません。安全監視モジュールはクロスワイヤショート監視機能を持つ必要はありませんが、必要に応じてクロスワイヤショート監視機能を無効にする必要があります。

- 適切なセーフティリレーユニットの選択に関する情報は、Schmersalのカタログか、インターネット (products.schmersal.com) 上にあるオンラインカタログをご覧ください。

4.4 シリアル診断 -SD

- 直列接続のオプション

SDコンポーネントを便利に直列接続するために、追加のアクセサリーとして、SD接続箱PFB-SD-4M12-SD (屋外用) とPDM-SD-4CC-SD (制御盤用) が用意されています。詳しくはインターネット (products.schmersal.com) をご覧ください。

- SD機器に配線する時には、ケーブルによる電圧降下や個々のコンポーネントの電流容量に配慮してください。

| セーフティスイッチの機能 | コネクタのピン配置 ST2、M12、8極 | 脱着式端子台の 構成 | DIN 47100に基づくシュメアザールコネクタのカラーコード | EN 60947-5-2に基づく市販のコネクタのカラーコード | ||

|---|---|---|---|---|---|---|

| 従来の診断機能付き | シリアル診断機能付き |  | ||||

| 24V | Ue | 1 | 1 | 白 | 茶 | |

| X1 | 安全入力 1 | 2 | 2 | 茶 | 白 | |

| GND | GND | 3 | 5 | 緑 | 青 | |

| Y1 | 安全出力 1 | 4 | 7 | 黄 | 黒 | |

| OUT | 診断出力 | SD 出力 | 5 | 9 | 灰 | 灰 |

| X2 | 安全入力 2 | 6 | 3 | ピンク | ピンク | |

| Y2 | 安全出力 2 | 7 | 8 | 青 | 紫 | |

| IN | 機能なし | SD入力 | 8 | 4 | 赤 | 橙 |

| 機能なし | - | 6 | ||||

| 配列 注文用端子台 サフィックス -SK または -CC | 配列取り外し可能な端子台付きバージョン | |

|---|---|---|

|  |  |

| カップリング付き接続ケーブル (メス) IP67 / IP69、M12、8極 - 8 x 0.25 mm²、DIN 47100 | |

|---|---|

| ケーブル長 | 型番 |

| 2,5 m | 103011415 |

| 5,0 m | 103007358 |

| 10,0 m | 103007359 |

| 15,0 m | 103011414 |

その他のケーブル長やアングル付きケーブル引き出しタイプはリクエストにより提供可能です。

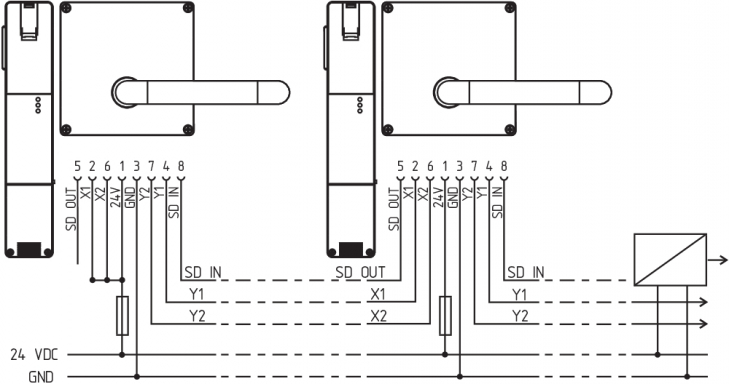

4.6 直列配線の配線例

直列配線が可能です。直列接続の場合、リスク時間は変わらず、反応時間は、技術データで指定された追加ユニットごとの入力の反応時間の合計だけ増加します。コンポーネントの数は、技術データに基づく外部ケーブルヒューズ保護と、ケーブル損失によってのみ制限されます。AZ201 … SDを直列診断付きで31個まで直列接続する事が可能です。

アプリケーション例を提示します。個々のアプリケーションに対して、スイッチ類やそのセットアップが適切かどうか、注意深くチェックしなければなりません。アプリケーション例を提示します。

配線例1:AZ201と従来の診断出力を直列配線します。

直列配線では、最後のコンポーネントまでのすべてのコンポーネントから 24V-X1-X2 ブリッジを削除する必要があります。電源は接続されたセーフティスイッチの最終(リレーユニットを基準として)で両方の安全入力にインプットされます。最初のセーフティコンポーネントの安全出力は、セーフティリレーユニットに接続されます。

Y1 と Y2 = 安全出力 → 安全リレーユニット

配線例2:シリアル診断機能付きAZ201の直列配線(最大31台直列)

シリアル診断機能 (順序接尾辞 -SD) を備えたデバイスでは、シリアル診断接続が直列に配線され、評価目的で SD ゲートウェイに接続されます。最初のセーフティコンポーネントの安全出力は、セーフティリレーユニットに接続されます。シリアル診断ゲートウェイは、最初のセーフティコンポーネントの診断入力に接続されます。

Y1 と Y2 = 安全出力 → 安全リレーユニット

SD-IN ゲートウェイ フィールドバス

5 アクチュエータのティーチング / アクチュエータ検出

標準コード化付きセーフティスイッチは、納入後直ぐに使用する事が出来ます。

個別コード化付きセーフティスイッチの場合、次の「ティーチング」手順が必要です。

- セーフティスイッチの電源を切り、再度オンにします。

- アクチュエータを検出領域に導きます。ティーチインはセーフティスイッチで通知され、緑色のLEDがオフになり、赤色のLEDが点灯し、黄色のLEDが点滅します(1Hz)。

- 10分後、短い黄色の点滅(3 Hz)の繰り返しで、セーフティスイッチの電源をオフにします。(電圧が5分以内にオフにされない場合、セーフティスイッチは「ティーチイン」手順をキャンセルし、5回の赤い点滅によって誤ったアクチュエーターに信号を送ります。)

- 動作電圧が再びオンになると、ティーチングされたアクチュエータ コードを有効にするために、アクチュエータをもう一度検出する必要があります。これにより、ティーチングされたアクチュエータの個別情報が保存されます。 (製品型式I2にて、新規アクチュエータのティーチング時は下記を参照ください)

suffix -I1の要求により、セーフティスイッチとアクチュエータの組み合わせは変更する事は出来ません。

型式末尾が -I2の場合、新しいアクチュエータでの「ティーチング」手順は制限なく繰り返す事が出来ます。新規アクチュエータのティーチング時に、これまでのコードは無効となります。その後、10分間ティーチングプロセス不可となり、より高度な無効化防止が保証されます。緑色LEDはティーチング行程不可の期間中点滅し、その後新規アクチュエータは検出されます。時間経過中に電源遮断が発生した場合、10分間の無効化保護時間が起動します。

6 動作原理と診断機能

6.1 バージョン毎の安全出力の動作

ガードが開くと、リスクのある時間内は安全出力が無効になります。

6.2 診断用LED

セーフティスイッチは、操作状況やエラーを前面に配置された3色LEDで表示します。

| 緑 (電源) | 動作電圧ON |

| 黄 (状態) | 動作状況 |

| 赤 (故障) | エラー (表参照2: エラーメッセージ / 赤色診断LEDの点滅コード) |

6.3 診断出力・電磁ロック付きインターロック

短絡保護のある診断出力は、表示用又はPLCなどの非安全関連制御部に使用可能です。

ガードが閉じている状態と、アクチュエーターが挿入されている状態は、24Vの信号で表示されます。

診断出力は安全性に関連する出力ではありません。

エラー

セーフティ スイッチギアの機能を保証できなくなるエラー (内部エラー) により、リスク期間内に安全出力が無効になります。エラーを修復した後、関連するガードを一旦開けて再び閉じると、エラーメッセージはリセットされます。

- 安全出力で複数のエラーが検出された場合、又はY1とY2の間で交差短絡が確認された場合、自動電子ロックが行われます。つまり通常のエラー確認は不可能です。こうしたインターロックをリセットするには、エラーの原因を排除した後、セーフティスイッチの電源をオフにする必要があります。

エラー警告

安全開閉装置の安全機能を直ちに危険にさらさない障害(周囲温度が高すぎる、外部電位での安全出力、交差回路など)は、シャットダウンの遅延につながります(表 2 を参照)。診断出力が遮断し、安全チャンネルが有効と言うこの組み合わせは、制御された方法で生産プロセスを停止する事に使用されます。エラー警告は原因が排除された際にリセットされます。障害警告が 30 分間継続すると、安全出力もオフになります (赤色の LED が点滅、表 2 を参照)。

| 表1: セーフティスイッチの診断情報 | |||||

|---|---|---|---|---|---|

| システム状況 | LED | 安全出力 Y1, Y2 | 診断出力 OUT -1P2P | ||

| 緑 | 赤 | 黄 | |||

| ドアが開いた状態 | On | Off | Off | 0 V | 0 V |

| ドア閉、アクチュエーター未挿入 | On | Off | Off | 0 V | 0 V |

| ドア閉, アクチュエーター挿入 | On | Off | On | 24 V | 24 V |

| エラー警告1), アクチュエーター挿入、遮断試行 | On | 点滅 2) | On | 24 V1) | 0 V |

| エラー | On | 点滅 2) | Off | 0 V | 0 V |

| 仕様 I1/I2 での追加: | |||||

| アクチュエータの教示行程開始 | Off | On | 点滅 | 0 V | 0 V |

| I2のみ: アクチュエーターの教示プロセス(ブロック解除) | 点滅 | Off | Off | 0 V | 0 V |

1) 30分後、安全出力遮断 2) 点滅コード参照 | |||||

| 表2: エラー表示 / 赤色診断LEDの点滅コード | |||

|---|---|---|---|

| 点滅コード (赤) | 表示 | 安全出力がOFFとなるまでの時間 | エラーの原因 |

| 1回点滅 | Y1出力のエラー(警告) | 30分 | 出力遮断時の出力テスト又はY1の電圧異常 |

| 2回点滅 | Y2出力のエラー(警告) | 30分 | 出力遮断時の出力テスト又はY2の電圧異常 |

| 3回点滅 | 交差短絡エラー(警告) | 30分 | 出力Y1、Y2の交差短絡または両方の出力エラー |

| 4回点滅 | 温度超過エラー(警告) | 30分 | 内部温度が高い |

| 5回点滅 | アクチュエーターのエラ | 0分 | 誤った又は欠陥のあるアクチュエータ |

| 6回点滅 | アクチュエータの組み合わせエラー | 0分 | 誤ったアクチュエータとの組み合わせ (ブロッキングボルトの検出又は無効化). |

| 赤連続点灯 | 内部エラー / 過電圧又は低電圧エラー | 0分 | 機器の故障 / 電圧が仕様の範囲にない |

6.4 シリアル診断機能SD付きセーフティスイッチ

シリアル診断ケーブル付きセーフティスイッチは、従来の診断出力ではなく、シリアル入出力ケーブルを持っています。セーフティスイッチが直列に接続されていると、診断データは直列配線した入出力を介して伝送されます。

最大31個のセーフティスイッチが直列に配線出来ます。シリアル診断ラインの評価には PROFIBUSゲートウェイ SD-I-DP-V0-2 またはユニバーサルゲートウェイ SD-I-U-... を使用します。このシリアル診断用インターフェースはスレーブとして既存のフィールドバスシステムに組み込めます。この様にして、診断信号はPLCで評価出来ます。

SDゲートウェイの接続に関する必要なソフトウェアは、products.schmersal.comからダウンロード出来ます。

応答データと診断データは、直列接続された個々のセーフティスイッチ用に、自動的且つ恒久的にPLCの入力バイトに書き込まれます。個々のセーフティスイッチ用の要求データは、PLCの出力バイトを介して、コンポーネントに伝送されます。フィールドバスゲートウェイとセーフティスイッチ間の通信エラーが発生した場合、セーフティスイッチのスイッチング状態が維持されます。

エラー

セーフティ スイッチギアの機能を保証できなくなるエラー (内部エラー) により、リスク期間内に安全出力が無効になります。原因が排除され故障が発生すると、安全出力は遮断されます。故障からの復帰が直ちに検出されないので、安全出力部の故障は次のリリース時に初めて削除されます。

- 安全出力で複数のエラーが検出された場合、又はY1とY2の間で交差短絡が確認された場合、自動電子ロックが行われます。つまり通常のエラー確認は不可能です。こうしたインターロックをリセットするには、エラーの原因を排除した後、セーフティスイッチの電源をオフにする必要があります。

エラー警告

セーフティ スイッチギアの安全機能を直ちに危険にさらさない障害 (たとえば、周囲温度が高すぎる、外部電位での安全出力、交差回路) は、シャットダウンの遅延につながります。診断出力が遮断し、安全チャンネルが有効と言うこの組み合わせは、制御された方法で生産プロセスを停止する事に使用されます。

エラー警告は原因が排除された際にリセットされます。

障害警告が 30 分間継続すると、安全出力もオフになります (赤色の LED が点滅)。

診断エラー(警告)

応答バイトにおいてエラー(警告)が発せられた場合、詳細な情報を読み出す事が出来ます。

| 表3: I/O データと診断データ (Bit = 1の時記述された状態になります) | ||||

|---|---|---|---|---|

| ビット番号 | 要求バイト | 応答バイト | 診断エラー警告 | 診断エラー |

| ビット 0: | --- | 安全出力動作 | Y1出力のエラー | Y1出力のエラー |

| ビット 1: | --- | アクチュエータ検出 | Y2出力のエラー | Y2出力のエラー |

| ビット 2: | --- | --- | 交差短絡 | 交差短絡 |

| ビット 3: | --- | --- | 温度超過 | 温度超過 |

| ビット 4: | --- | X1 と X2の入力状態 | --- | 誤った又は欠陥のあるアクチュエータ |

| ビット 5: | --- | ガード検出 | 内部機器エラー | 内部機器エラー |

| ビット 6: | --- | エラー警告 1) | フィールドバス・ゲートウェイとセーフティスイッチ間の通信エラー | --- |

| ビット 7: | エラーリセット | エラー(安全出力OFF) | --- | --- |

| 1) 30後 -> エラー | ||||

7 立ち上げと保全

セーフティコンポーネントの安全機能をテストする必要があります。正しく取り付けられ、適切に使用されていれば、セーフティスイッチはメンテナンスフリーです。通常の目視及び機能テストに加えて、以下のチェックを推奨します。

- アクチュエータと電磁ロック付きインターロックが安全に取り付けられているかチェックします

- アクチュエータと電磁ロック付きインターロックの横方向の最大ズレをチェックしてください。

- ケーブルコネクターが確実に取り付けられているか

- ハウジングの損傷を確認してください。

- ゴミや汚れを取り除く。

- 例えば予備のアクチュエータを使うなどする無効化に対する保護のために、そしてガードの無効化防止のために、適切な方策を講じなければなりません。

- 破損、故障の場合は交換してください。

8 取り外し・廃棄

8.1 取り外し

セーフティスイッチの取り外しは非通電状態で行わなければなりません。

8.2 廃棄処分

- セーフティスイッチは国家規格や法規に従って、適切な措置により廃棄しなければなりません。

9 付録 – 特殊仕様

特殊仕様 -2965-1

| カップリング付き接続ケーブル (メス) IP67, M23, 12極 - 12 x 0.75 mm² | |

|---|---|

| ケーブル長 | 型番 |

| 5.0 m | 101208520 |

| 10.0 m | 103007354 |

| 20.0 m | 101214418 |

特殊仕様-2965-2

| カップリング付き接続ケーブル (メス) IP67, M23, 8+1極 - 9 x 0.75 mm² | |

|---|---|

| ケーブル長 | 型番 |

| 5.0 m | 101209959 |

| 10.0 m | 101209958 |

| 15.0 m | 103001384 |

| カップリング付き接続ケーブル (メス) IP67, M12, 8極 - 8 x 0.25 mm² | |

|---|---|

| ケーブル長 | 型番 |

| 2.5 m | 103011415 |

| 5.0 m | 103007358 |

| 10.0 m | 103007359 |

特殊仕様 -2965-3

| カップリング付き接続ケーブル (メス) IP67, M12, 8極 - 8 x 0.25 mm² | |

|---|---|

| ケーブル長 | 型番 |

| 2.5 m | 103011415 |

| 5.0 m | 103007358 |

| 10.0 m | 103007359 |

| UK Declaration of Conformity |  |

| Company: | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby, under sole responsibility, certify that the hereafter described components both in their basic design and construction conform to the relevant statutory requirements, regulations and designated standards of the United Kingdom. |

| Name of the component: | AZ201 |

| Type: | See ordering code |

| Description of the component: | Safety Switch for safety functions |

| Relevant legislation: | Supply of Machinery (Safety) Regulations | 2008 |

| Radio Equipment Regulations | 2017 | |

| The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations | 2012 |

| Designated standards: | EN 60947-5-3:2013 ISO 14119:2013 EN 300 330 V2.1.1:2017 EN ISO 13849-1:2015 EN 61508 parts 1-7:2010 |

| Approved body for Type Examination: | TÜV Rheinland UK Ltd. 1011 Stratford Road Solihull, B90 4BN ID: 2571 |

| Type examination certificate: | 01/205U/5608.00/22 |

| UK-Importer / Person authorised for the compilation of the technical documentation: | Schmersal UK Ltd. Paul Kenney Unit 1, Sparrowhawk Close Enigma Business Park Malvern, Worcestershire, WR14 1GL |

| Place and date of issue: | Wuppertal, September 28, 2022 |

|

| Authorised signature Philip Schmersal Managing Director |

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | AZ201 |

| Type: | See ordering code |

| Description of the component: | Safety Switch for safety functions |

| Relevant Directives: | Machinery Directive | 2006/42/EC |

| RED-Directive | 2014/53/EU | |

| RoHS-Directive | 2011/65/EU |

| Applied standards: | EN 60947-5-3:2013 ISO 14119:2013 EN 300 330 V2.1.1:2017 EN ISO 13849-1:2015 EN 61508 parts 1-7:2010 |

| Notified body for Type Examination: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| EC-Type Examination Certificate: | 01/205/5608.00/17 |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, May 21, 2021 |

|

| Authorised signature Philip Schmersal Managing Director |

シュメアザー株式会社, 〒222-0033 横浜市港北区新横浜3-9-5, 新横浜第3東昇ビル

データと詳細は完全にチェックされました。画像は元の画像と異なる場合があります。技術的なデータはマニュアルで見られます。技術的に変更されたり、エラーの可能性があります。

Generated on 2025/08/17 12:06

.png?id=63182abd9f3f42c5479fde3c4f28d70c)