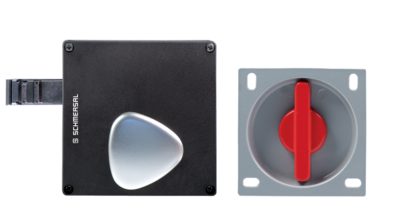

AZM 200 BZ ST-T-AS AP

AZM 200 BZ ST-T-AS AP

- Solenoid supply 24 VDC (Aux)

- Combined monitoring of actuator and solenoid interlock

- Solenoid interlock

- Thermoplastic enclosure

- High holding force 2000

- 40 mm x 244 mm x 50 mm

- Interlock with protection against incorrect locking.

- Double-insulated

- Long life

- Integrated AS-Interface

Ordering data

| Note (Delivery capacity) |

Not available! |

| Product type description |

AZM 200 BZ ST-T-AS AP |

| Article number (order number) |

101194500 |

| EAN (European Article Number) |

4030661364858 |

| eCl@ss number, version 12.0 |

27-27-26-03 |

| eCl@ss number, version 11.0 |

27-27-26-03 |

| eCl@ss number, version 9.0 |

27-27-26-03 |

| ETIM number, version 7.0 |

EC002593 |

| ETIM number, version 6.0 |

EC002593 |

Approvals - Standards

| Certificates |

cULus ASi-SaW |

General data

| Standards |

EN IEC 62026-2 EN ISO 13849-1 EN IEC 60947-5-1 EN IEC 60947-5-3 EN IEC 61508 |

| Coding |

Universal coding |

| Coding level according to EN ISO 14119 |

Low |

| Working principle |

electromechanical |

| Housing material |

Plastic, glass-fibre reinforced thermoplastic, self-extinguishing |

| Reaction time, maximum |

60 ms |

| Duration of risk, maximum |

120 ms |

| Gross weight |

520 g |

General data - Features

| Power to lock |

Yes |

| Actuator and interlock combined monitored |

Yes |

| Integral system diagnostics, status |

Yes |

| Number of actuating directions |

1 |

| Safety classification |

| Standards |

EN IEC 60947-5-3 EN IEC 61508 |

| Performance Level, up to |

e |

| Category |

4 |

| PFH value |

4.00 x 10⁻⁹ /h |

| Safety Integrity Level (SIL), suitable for applications in |

3 |

| Mission time |

20 Year(s) |

Mechanical data

| Mechanical lifetime, minimum |

1,000,000 Operations |

| Holding force FZh in accordance with EN ISO 14119 |

2,000 N |

| Note (clamping force FZh) |

1,000 N when used with the AZ/AZM201-B30 actuator, for indoor use. |

| Holding force Fmax, maximum |

2,600 N |

| Note (clamping force Fmax) |

1.300 N in Verbindung mit einem Betätiger AZ/AZM201-B30 für Innenanbau. |

| Latching force |

30 N |

| Actuating speed, maximum |

2 m/s |

| Tightening torque of the screw, maximum |

1 Nm |

| Tightening torque of the fastening screws for the housing cover, minimum |

0.7 Nm |

| Tightening torque of the fastening screws for the housing cover, maximum |

1 Nm |

| Note |

Torx T10 |

Mechanical data - Connection technique

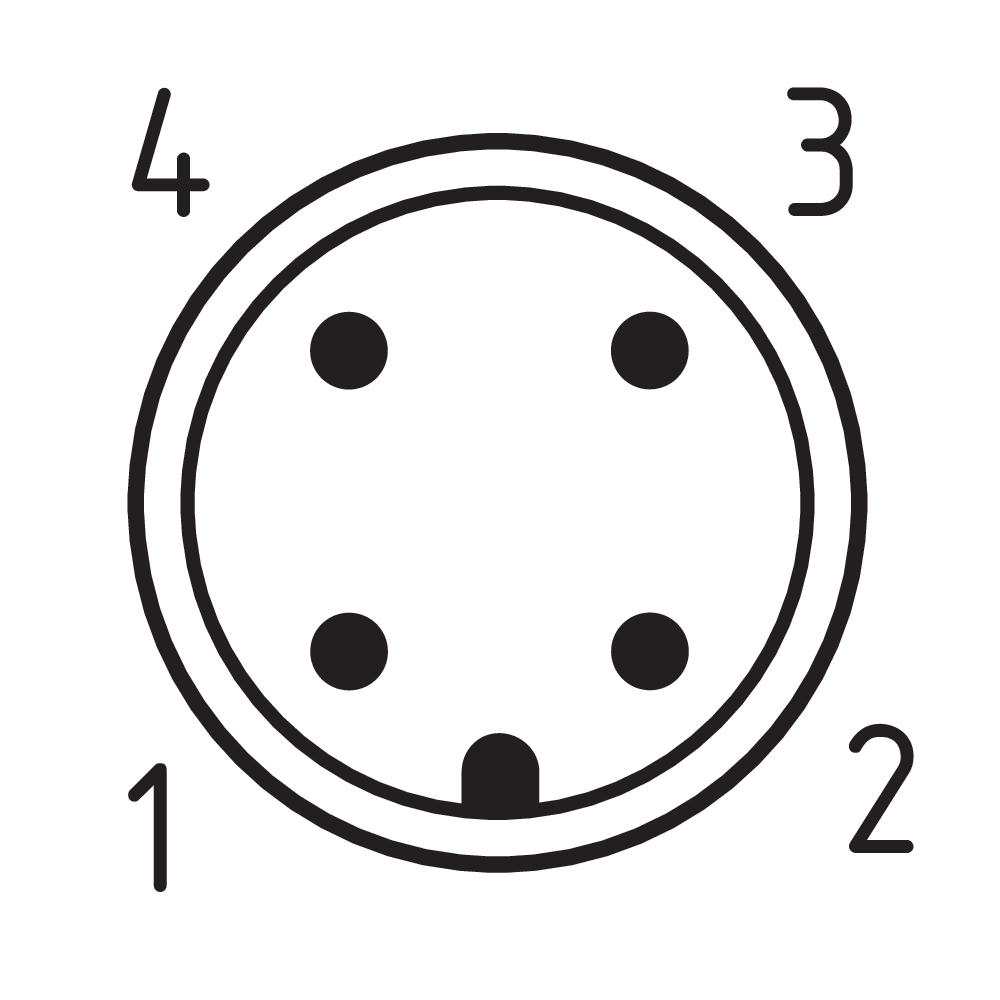

| Termination |

Connector plug M12, 4-pole, (A-coding) |

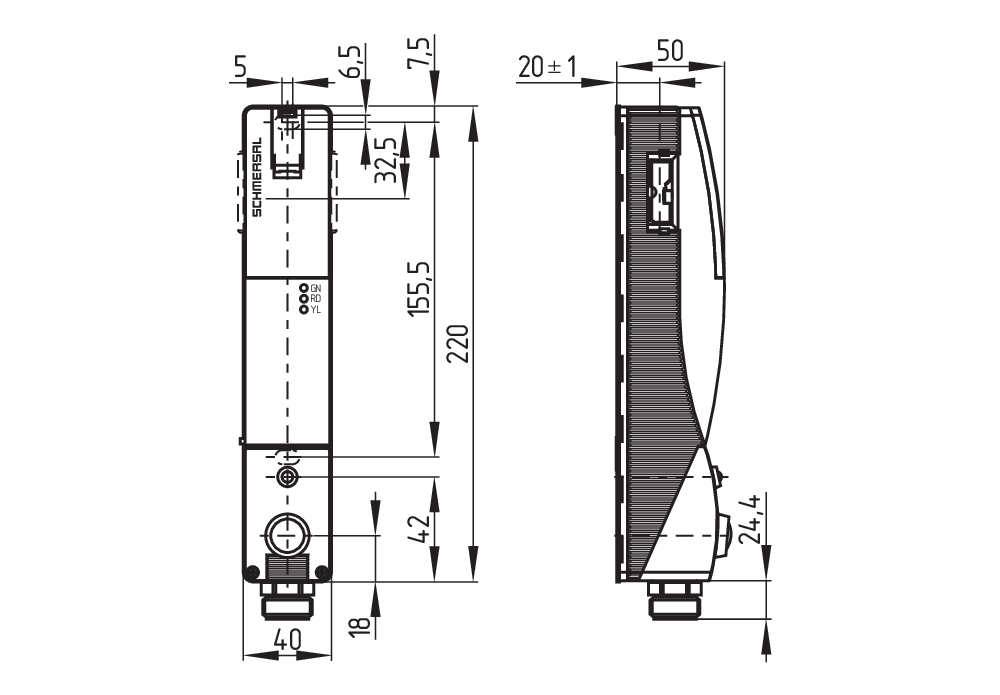

Mechanical data - Dimensions

| Length of sensor |

50 mm |

| Width of sensor |

40 mm |

| Height of sensor |

244 mm |

Ambient conditions

| Degree of protection |

IP67 |

| Ambient temperature |

-25 ... +60 °C |

| Storage and transport temperature |

-25 ... +85 °C |

| Relative humidity, minimum |

30 % |

| Relative humidity, maximum |

95 % |

| Note (Relative humidity) |

non-condensing |

| Resistance to vibrations |

10 … 150 Hz, amplitude 0.35 mm |

| Restistance to shock |

30 g / 11 ms |

| Protection class |

II |

Ambient conditions - Insulation values

| Rated insulation voltage Ui |

32 VDC |

| Rated impulse withstand voltage Uimp |

0.8 kV |

| Overvoltage category |

III |

| Degree of pollution |

3 |

Electrical data

| Time to readiness, maximum |

4,000 ms |

Electrical data - AS Interface

| Rated operating voltage |

26.5 ... 31.6 VDC (Protection against polarity reversal) |

| AS-i Current consumption, maximum |

100 mA |

Electrical data - AS-Interface specification

| AS-i Specification |

Safety-Slave |

| AS-i Version |

V 2.1 |

| AS-i Profile |

S-7.B.F.E |

| AS-i, IO-Code |

0x7 |

| AS-i, ID-Code |

0xB |

| AS-i, ID-Code1 |

0xF |

| AS-i, ID-Code2 |

0xE |

| AS-i Input, Channel 1 |

Data bits DI 0 / DI 1 = dynamic code transmission |

| AS-i Input, Channel 2 |

Data bits DI 2 / DI 3 = dynamic code transmission |

| AS-i Outputs, DO 0 |

Solenoid control |

| AS-i Outputs, DO 1 |

No Function |

| AS-i Outputs, DO 2 |

No Function |

| AS-i Outputs, DO 3 |

No Function |

| AS-i Parameter bits, P0 |

Safety guard and actuator detected |

| AS-i Parameter bits, P1 |

Solenoid interlock locked |

| AS-i Parameter bits, P2 |

Magnet voltage in tolerance range |

| AS-i Parameter bits, P3 |

Error |

| Note (AS-i Parameter bits) |

Set the parameter outputs to "1111" (0xF) FID: periphery error |

| AS-i Input module address |

0 |

| Note (AS-i Input module address) |

Preset to address 0, can be changed through AS-interface bus master or hand-held programming device |

Electrical data - Auxiliary voltage

| Operating voltage |

24 VDC -15 % / +10 % (stabilised PELV power supply) |

| Current consumption |

500 mA |

| Rated operating voltage |

24 VDC |

| Fuse rating |

4 A |

Electrical data - Magnet control

| Magnet switch-on time |

100 % |

Status indication

| Note (LED switching conditions display) |

(1) LED green-red (AS-i Duo LED): Supply voltage / Communication error / Slave address = 0 (2) LED red: Internal device error (3) LED yellow: Device condition |

Other data

| Note (applications) |

sliding safety guard removable guard hinged safety guard |

Pin assignment

| PIN 1 |

AS-i + |

| PIN 2 |

Aux - (P) |

| PIN 3 |

AS-Interface - |

| PIN 4 |

Aux + (P) |

Scope of delivery

| Scope of delivery |

Actuator must be ordered separately. |

Note

| Note (General) |

Interlocks with the power to lock principle may only be used in special cases after a thorough evaluation of the accident risk, since the guarding device can immediately be opened on failure of the electrical power supply or when the main switch is opened. |

| Note voltage AUX DC |

stabilised PELV power supply |

Language filter

Datasheet

Operating instructions and Declaration of conformity

UL Certificate

AS interface safety at work certificate

SISTEMA-VDMA library

Download the latest version of Adobe Reader

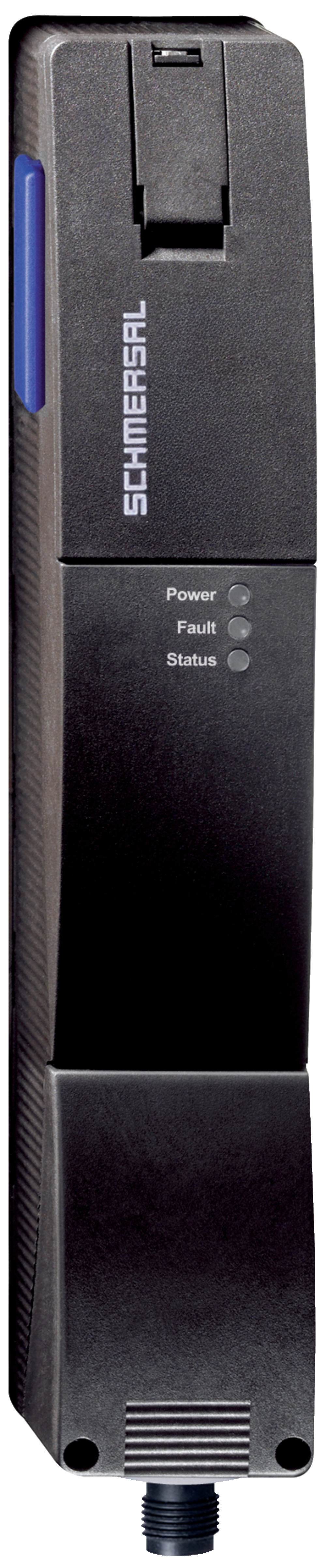

Product picture (catalogue individual photo)

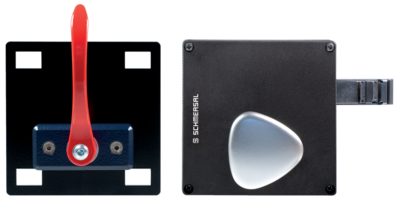

Contact arrangement

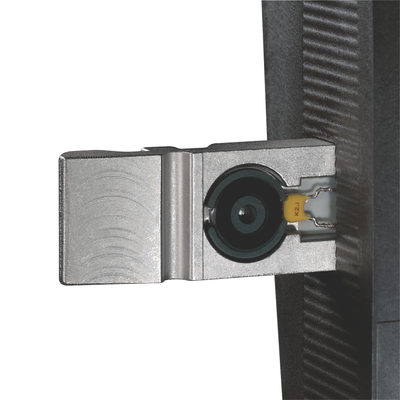

Assembly example

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | AZM 200 AS |

| Type: | See ordering code |

| Description of the component: | Interlocking device with electromagnetic interlock for safety functions with integrated AS-i Safety at Work |

| Relevant Directives: | Machinery Directive | 2006/42/EC |

| EMC-Directive | 2014/30/EU | |

| RoHS-Directive | 2011/65/EU |

| Applied standards: | EN 60947-5-3:2013 ISO 14119:2013 EN ISO 13849-1:2015 EN 61508 parts 1-7:2010 EN 62061:2005 + AC:2010 + A1:2013 + A2:2015 |

| Notified body for Type Examination: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| EC-Type Examination Certificate: | 01/205/5122.02/20 |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, February 26, 2020 |

|

| Authorised signature Philip Schmersal Managing Director |

K.A. Schmersal GmbH & Co. KG, Möddinghofe 30, 42279 Wuppertal

The details and data referred to have been carefully checked. Images may diverge from original. Further technical data can be found in the manual. Technical amendments and errors possible.

Generated on: 17/09/2025, 13:30

.png?id=bb44e9061d048e5250879d3fc4285be0)