EX-AZM300B-ST-1P2P-A-CR-3GD

| 製品タイプの説明: EX-AZM300(1)(2)-ST(3)(4)(5) |

| (1) | |

| Z | ロック監視 > |

| B | アクチュエーター監視 |

| (2) | |

| なし | 標準コード化 |

| I1 | 個別コード化 |

| I2 | 個別コード化 複数のティーチング |

| (3) | |

| 1P2P | 1 PNPタイプ診断出力及び2 PNPタイプ安全出力 |

| SD2P | シリアル診断出力及び2 PNP安全出力 |

| (4) | |

| なし | スプリングロック |

| A | マグネットロック |

| (5) | |

| CL | 保護エンクロージャー付き、ドアヒンジ左 |

| CR | 保護エンクロージャー付き、ドアヒンジ右 |

- Exゾーン 2 及び 22

- 要求に基づいた無効化防止のためのRFID技術

- 熱可塑性樹脂性ケース

- プロファイルシステムへの取り付けに適します

- ヒンジ・スライド式扉用

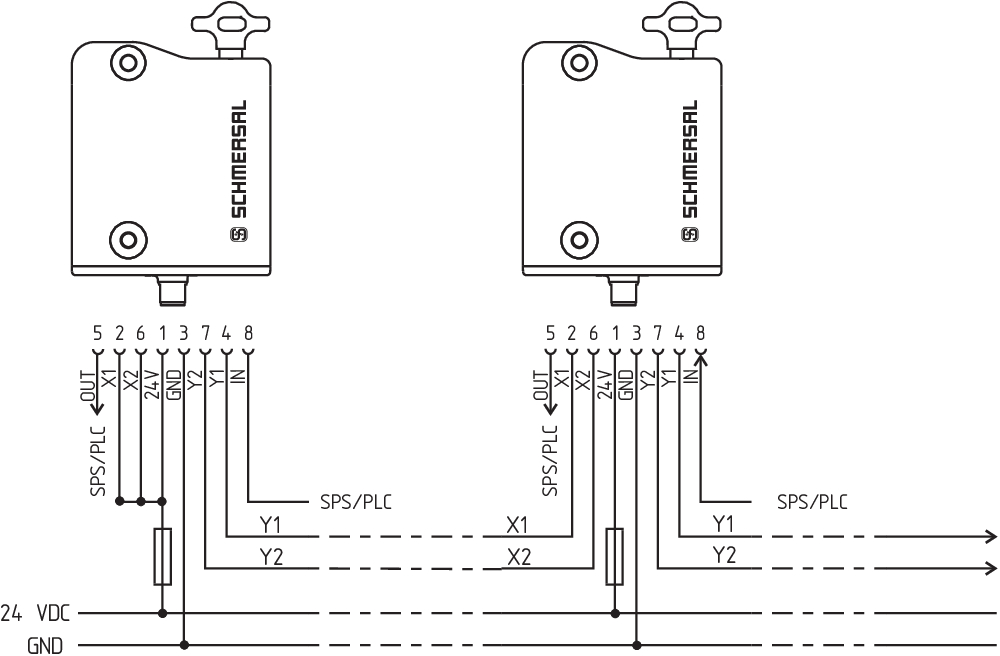

- 直列接続

- マニュアル・リリース

注文データ

| 製品タイプの説明 |

EX-AZM300B-ST-1P2P-A-CR-3GD |

| 部品番号(注文番号) |

103012540 |

| EAN(欧州部品番号) |

4030661483917 |

| eCl@ss番号、バージョン12.0 |

27-27-26-03 |

| eCl@ss番号、バージョン11.0 |

27-27-26-03 |

| eCl@ss番号、バージョン9.0 |

27-27-26-03 |

| ETIM番号、バージョン7.0 |

EC002593 |

| ETIM番号、バージョン6.0 |

EC002593 |

認証

|

TÜV ATEX (Konformitätserklärung) |

防爆

| 防爆:規則 |

EN IEC 60079-0 EN 60079-7 EN 60079-31 |

| 防爆ゾーン |

2 22 |

| 防爆 カテゴリー |

3G 3D |

| 防爆指定 |

D II 3G Ex ic IIC T5 Gc X D II 3D Ex tc IIIB T95°C Dc X |

一般データ

| 規格 |

EN ISO 13849-1 EN ISO 14119 EN IEC 60947-5-3 EN IEC 61508 |

| 一般情報 |

ユニバーサルコード化 |

| EN ISO 14119に準拠したコーディングレベル |

Low |

| アクティブ原理 |

RFID |

| 周波数帯、RFID |

125 kHz |

| 送信機出力 RFID、最大 |

-6 dBm |

| ハウジング 材質 |

樹脂、グラスファイバー強化熱可塑性樹脂、自己消火性 |

| リスク持続時間、最大 |

200 ms |

| アクチュエーターの応答時間、最大 |

100 ms |

| 入力の応答時間、最大 |

1.5 ms |

| 総重量 |

1,056 g |

一般データ - 仕様

| マグネットロック |

Yes |

| アクチュエーター監視 |

Yes |

| ラッチング |

Yes |

| 手動解除 |

Yes |

| 短絡検出 |

Yes |

| 短絡監視 |

Yes |

| 直列接続 |

Yes |

| 安全機能 |

Yes |

| 一体型システム診断、状態 |

Yes |

| 動作方向の数 |

1 |

| フェイルセーフデジタル出力の数 |

2 |

安全性評価

| 規定 |

EN ISO 13849-1 EN IEC 61508 |

安全性評価 - インターロック

| パフォーマンスレベル、最大 |

e |

| カテゴリー |

4 |

| PFH値 |

5.20 x 10⁻¹⁰ /h |

| PFD値 |

4.50 x 10⁻⁵ |

| 安全インテグリティレベル (SIL), 安全度水準に適合 |

3 |

| ミッションタイム |

20 年 |

機械的データ

| 機械的寿命、最小 |

1,000,000 操作 |

| 注記(機械的寿命) |

When using as door stop: ≥ 50.000 operations (door mass ≤ 5 kg and actuating speed ≤ 0.5 m/s) |

| スイッチ本体とアクチュエータ間の角度の公差、最大 |

2 ° |

| 衝撃エネルギー, (保護ケース)、最大 |

7 J |

| 注意、(衝撃エネルギー) |

ステンレススチールCL/CR保護エンクロージャ |

| ロック時引抜き強度 FZh EN ISO 14119 に準拠 |

1,150 N |

| ロック時引抜き強度 Fmax, 最大 |

1,500 N |

| 力、ラッチ力、調整可能、位置 1 |

25 N |

| 力、ラッチ力、調整可能、位置 2 |

50 N |

| 固定ネジの種類 |

2x M6 |

| 注意 (固定ネジの種類) |

物件クラス最低8.8 |

| 固定ネジの最大締付けトルク, |

8 Nm |

| 取り付けネジの材質 |

ステンレス鋼 (V4A) |

Mechanical data - Switching distances

| 切替距離、 典型的な |

2 mm |

| 安定動作距離 "ON" Sao |

1 mm |

| 安定動作距離 "OFF" Sar |

20 mm |

| 注記 (動作距離) |

All switching distances in accordance EN IEC 60947-5-3 |

機械的データ - 電気機械式

| センサーチェーンの長さ、最大 |

200 m |

| 注意(センサーチェーンの長) |

ケーブル長とケーブル径により、出力電流による電圧降下が変化します。 |

| 注意 (直列接続) |

無制限のデバイス数,外部ラインヒューズオーバーサーブ、シリアル診断SDの場合、最大31デバイス。 |

| 接続 |

M12コネクター, 8芯, Aコード化 |

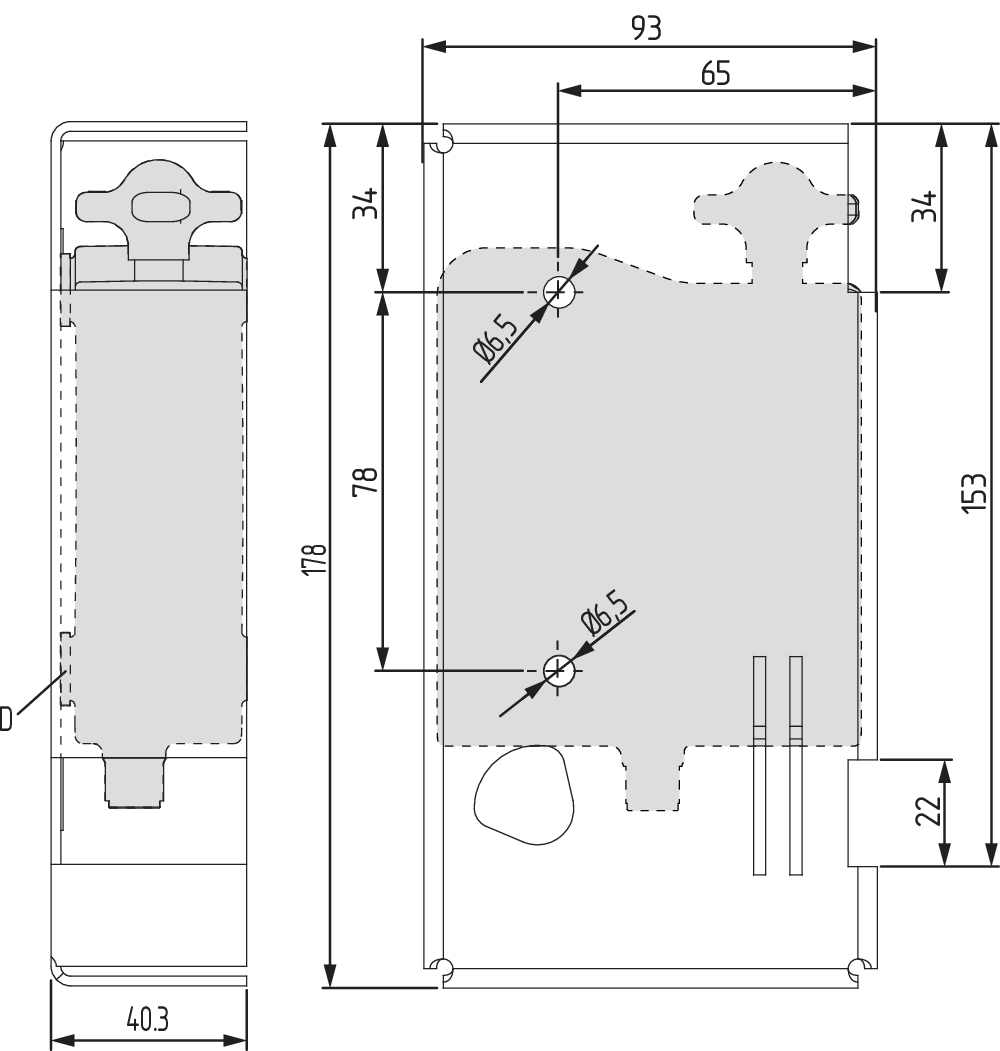

機械的データ - 寸法

| センサー長 |

178 mm |

| センサーの幅 |

93 mm |

| センサーの高さ |

40.3 mm |

環境条件

| 保護等級 |

IP66 IP67 IP69 |

| 使用周囲温度 |

+0 ... +50 °C |

| 保管および輸送温度 |

-10 ... +90 °C |

| 相対湿度, 最大 |

93 % |

| 注記 (相対湿度) |

non-condensing non-icing |

| 耐振動 |

10 ~ 150 Hz、振幅 0.35 mm |

| 耐衝撃 |

30 g / 11 ms |

| 保護等級 |

III |

| 許容される設置高度/標高(海抜), 最大 |

2,000 m |

環境条件 - 絶縁値

| 定格絶縁電圧 Ui |

32 VDC |

| 定格インパルス耐電圧 Uimp |

0.8 kV |

| 過電圧カテゴリー |

III |

| 汚染度 |

3 |

電気的データ

| 動作電圧 |

24 VDC -15 % / +10 % (PELV電源により安定化) |

| 無負荷供給電流 I0, 典型的 |

100 mA |

| マグネットON時の消費電流(平均 |

200 mA |

| マグネットON時の消費電流、ピーク |

350 mA / 200 ms |

| 定格動作電圧 |

24 VDC |

| 動作電流 |

800 mA |

| 要求定格短絡電流 |

100 A |

| 外部ワイヤとデバイスのヒューズ定格 |

2 A gG |

| 準備時間、最大 |

5,000 ms |

| 開閉頻度、最大 |

0.5 Hz |

| 使用カテゴリー DC-12 |

24 VDC / 0.05 A |

| 電気的ヒューズ定格、最大 |

2 A |

電気的データ - ソレノイド制御

| 指定、ソレノイド |

IN |

| スイッチングのしきい値 |

-3 V … 5 V (Low) 15 V … 30 V (High) |

| 24Vの時の消費電流 |

10 mA |

| マグネット起動時間 |

100 % |

| テストパルス幅、最大 |

5 ms |

| テストパルス間隔、最小 |

40 ms |

| 分類 ZVEI CB24I、シンク |

C0 |

| 分類 ZVEI CB24I、ソース |

C1 C2 C3 |

Electrical data - Safety digital inputs

| 指定、安全入力 |

X1 and X2 |

| スイッチングのしきい値 |

−3 V … 5 V (Low) 15 V … 30 V (High) |

| 24Vの時の消費電流 |

5 mA |

| テストパルス幅、最大 |

1 ms |

| テストパルス間隔、最小 |

100 ms |

| 分類 ZVEI CB24I、シンク |

C1 |

| 分類 ZVEI CB24I、ソース |

C1 C2 C3 |

Electrical data - Safety digital outputs

| 指定、安全出力 |

Y1 and Y2 |

| 制御エレメントのデザイン |

short-circuit proof, p-type |

| 電圧降下 Ud、最大 |

2 V |

| 残留電流 lr, 最大 |

0.5 mA |

| 電圧, 使用カテゴリー DC-12 |

24 VDC |

| 電流、使用カテゴリーDC-12 |

0.25 A |

| 電圧, 使用カテゴリー DC-13 |

24 VDC |

| 電流、使用カテゴリーDC-13 |

0.25 A |

| テストパルス間隔、標準 |

1000 ms |

| テストパルス幅、最大 |

0.5 ms |

| 分類 ZVEI CB24I、ソース |

C2 |

| 分類 ZVEI CB24I、シンク |

C1 C2 |

電気的データ - 診断出力

| 指定、診断出力 |

OUT |

| 制御エレメントのデザイン |

short-circuit proof, p-type |

| 電圧降下 Ud、最大 |

2 V |

| 電圧, 使用カテゴリー DC-12 |

24 VDC |

| 電流、使用カテゴリーDC-12 |

0.05 A |

| 電圧, 使用カテゴリー DC-13 |

24 VDC |

| 電流、使用カテゴリーDC-13 |

0.05 A |

状態表示

| 注記 (LED切り替え状態表示) |

Operating condition: LED green Error / functional defect: LED red Supply voltage UB: LED green |

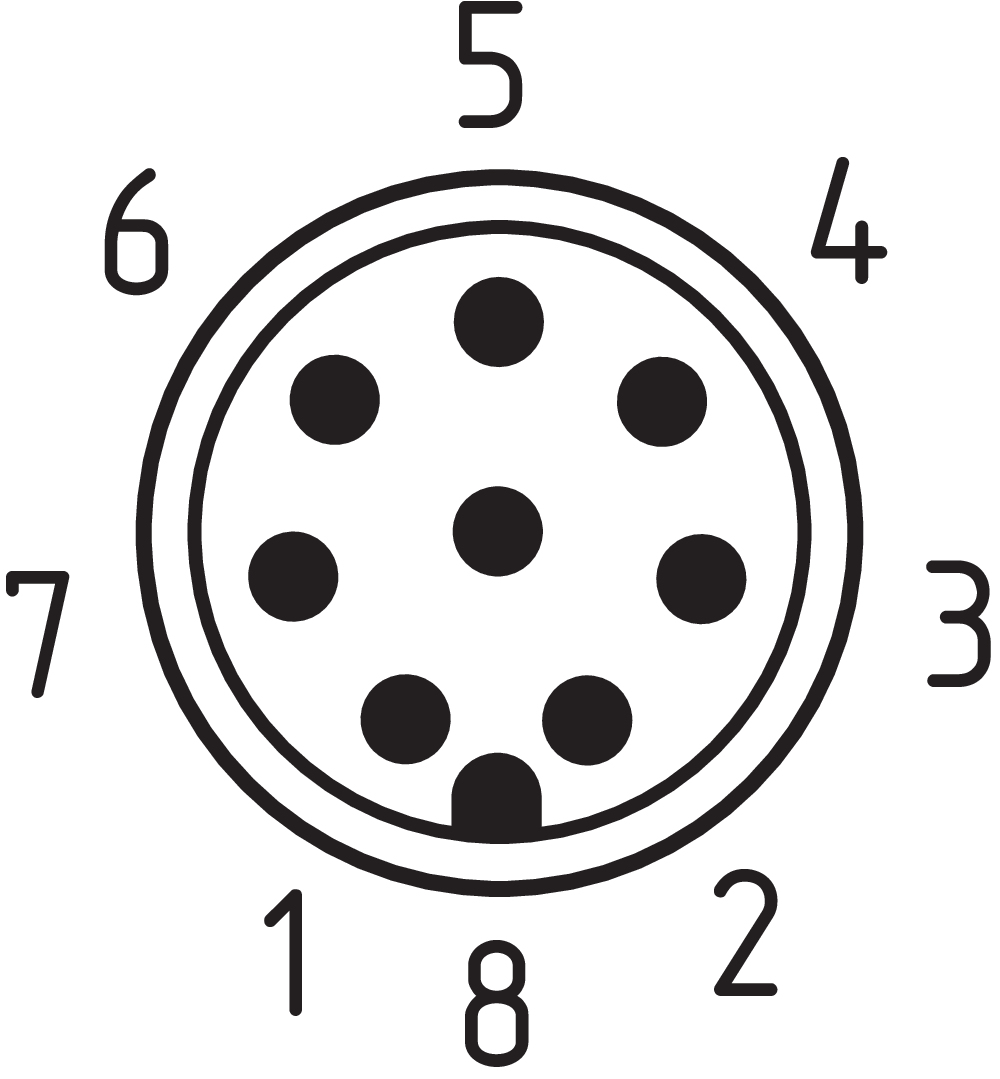

ピン配列

| ピン 1 |

A1 Supply voltage UB |

| ピン 2 |

X1 Safety input 1 |

| ピン 3 |

A2 GND |

| ピン 4 |

Y1 Safety output 1 |

| ピン 5 |

OUT Diagnostic output |

| ピン 6 |

X2 Safety input 2 |

| ピン 7 |

Y2 Safety output 2 |

| ピン 8 |

IN Solenoid control |

納入品目

| 納入時同梱 |

Actuator must be ordered separately. |

アクセサリー

| 推奨(アクチュエーター) |

EX-AZ/AZM300-B1 |

Note

| 注記 (一般) |

For doors that are flush with the door frame, the optional mounting plate MP-AZ/AZM300-1 can be used. For glass and Makrolon doors, the optional mounting kit MS-AZ/AZM300-B1-1 can be used. As long as the actuating unit remains inserted in the solenoid interlock, the unlocked safety guard can be relocked. In this case, the safety outputs are re-enabled, so that the safety guard must not be opened. |

言語フィルター

データシート

Operating instructions and Declaration of conformity

UKCA Declaration of Conformity

BG-test certificate

SISTEMA-VDMA library

Adobe Readerの最新版をダウンロードしてください

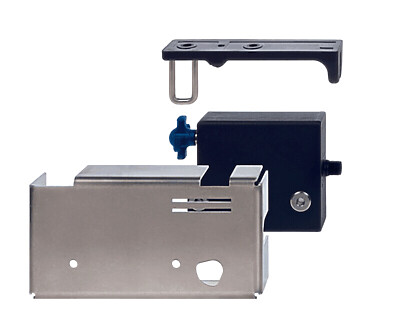

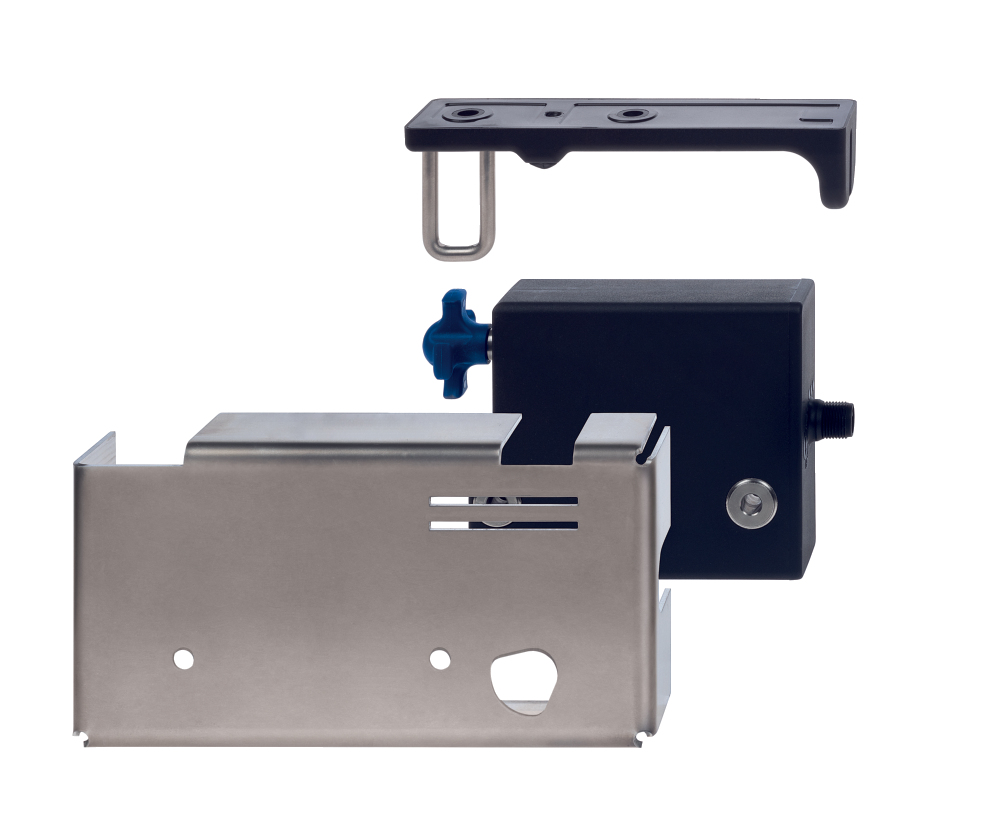

Product picture (catalogue individual photo)

Dimensional drawing basic component

Wiring example

Contact arrangement

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | EX-AZM300...-3GD |

| Type: | See ordering code |

| Marking: | D II 3G Ex ec IIB T5 Gc D II 3D Ex tc IIIB T95°C Dc X |

| Description of the component: | Interlocking device with electromagnetic interlock for safety functions |

| Applicable directives: | Machinery Directive | 2006/42/EC |

| RED-Directive | 2014/53/EU | |

| Explosion Protection Directive (ATEX) | 2014/34/EU | |

| RoHS Directive | 2011/65/EU |

| Applied standards: | IEC 60947-5-3:2013 EN ISO 14119:2013 EN 300 330 V2.1.1:2017 EN IEC 60079-0:2018 EN 60079-7:2015 EN 60079-31:2014 EN ISO 13849-1:2015 IEC 61508 parts 1-7:2010 |

| Notified body for Type Examination in accordance with the Machinery Directive 2006/42/EC: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| EC test certificate in accordance with the Machinery Directive 2006/42/EC: | 01/205/5281.03/20 |

| Conformity with the explosion protection directive 2014/34/EU (ATEX) is declared by the manufacturer without involving a test center. |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, August 9, 2022 |

|

| Authorised signature Philip Schmersal Managing Director |

| UK Declaration of Conformity |  |

| Company: | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby, under sole responsibility, certify that the hereafter described components both in their basic design and construction conform to the relevant statutory requirements, regulations and designated standards of the United Kingdom. |

| Name of the component: | EX-AZM300 ...-3GD |

| Type: | See ordering code |

| Marking: | D II 3G Ex ec IIB T5 Gc D II 3D Ex tc IIIB T95°C Dc X |

| Description of the component: | Interlocking device with electromagnetic interlock for safety functions |

| Relevant legislation: | Supply of Machinery (Safety) Regulations | 2008 |

| Electromagnetic Compatibility Regulations | 2016 | |

| Equipment and Protective Systems intended for use in Potentially Explosive Atmospheres Regulations | 2016 | |

| The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations | 2012 |

| Designated standards: | IEC 60947-5-3:2013, EN ISO 14119:2013, EN 300 330 V2.1.1:2017, EN IEC 60079-0:2018, EN 60079-7:2015, EN 60079-31:2014, EN ISO 13849-1:2015, IEC 61508 parts 1-7:2010 |

| Approved body for Type Examination: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| Type examination certificate: | 01/205/5281.03/20 |

| Conformity with SI 2016/1107 (Equipment and Protective Systems intended for use in Potentially Explosive Atmospheres Regulations) is declared by the manufacturer without involving a conformity assessment center. |

| UK-Importer / Person authorised for the compilation of the technical documentation: | Schmersal UK Ltd. Paul Kenney Unit 1, Sparrowhawk Close Enigma Business Park Malvern, Worcestershire, WR14 1GL |

| Place and date of issue: | Wuppertal, November 10, 2022 |

|

| Authorised signature Philip Schmersal Managing Director |

シュメアザール株式会社, 〒222-0033 横浜市港北区新横浜3-9-5, 新横浜第3東昇ビル

データと詳細は完全にチェックされました。画像は元の画像と異なる場合があります。技術的なデータはマニュアルで見られます。技術的に変更されたり、エラーの可能性があります。

Generated on 2025/10/15 5:52

.png?id=63182abd9f3f42c5479fde3c4f28d70c)