RSS260-I2-D-LSTM12-5-0,25M

RSS260-I2-D-LSTM12-5-0,25M

| Product type description: RSS260-(1)-(2)-(3)-(4)-(5) |

| (1) | |

| without | Standard coding |

| I1 | Individual coding |

| I2 | Individual coding, multiple teaching |

| (2) | |

| D | With diagnostic output |

| SD | With serial diagnostic function 1) |

| (3) | |

| without | Standard version without feedback circuit monitoring EDM (External Device Monitoring) |

| F0 | EDM with automatic reset 1) |

| F1 | EDM with manual reset 1) |

| (4) | |

| without | Without EMERGENCY STOP |

| Q | Acknowledge input error with EMERGENCY STOP 1) |

| (5) | |

| without | Connecting cable (lenght in m) |

| ST | Connector plug M8, 8-pole |

| LSTM12-8-0,25M | Cable 0.25 m long with connector M12, 8-pole |

| LSTM8-8-0,1M | Cable 0.1 m long with connector M8, 8-pole |

| LSTM12-5-0.25M | Cable 0.25 m long with connector M12, 5-pole |

| (*) | |

| 1) | only for versions -ST, -LSTM12-8-0.25M and -LSTM8-8-0.1M |

- 5-pole cable connector M12 for individual connection

- Repeated individual coding with RFID technology

- Coding level "High" according to ISO 14119

- Simple mounting without additional angle

- Frontal and lateral actuation enabled

- RFID-technology for needs-based protection against tampering

- Thermoplastic enclosure

Ordering data

| Product type description |

RSS260-I2-D-LSTM12-5-0,25M |

| Article number (order number) |

103025103 |

| EAN (European Article Number) |

4030661512259 |

| eCl@ss number, version 12.0 |

27-27-46-01 |

| eCl@ss number, version 11.0 |

27-27-24-03 |

| eCl@ss number, version 9.0 |

27-27-24-03 |

| ETIM number, version 7.0 |

EC001829 |

| ETIM number, version 6.0 |

EC001829 |

Approvals - Standards

| Certificates |

TÜV cULus FCC IC ANATEL |

General data

| Standards |

EN ISO 13849-1 EN IEC 60947-5-3 EN IEC 61508 |

| Coding |

Individual coding, multiple teaching |

| Coding level according to EN ISO 14119 |

High |

| Working principle |

RFID |

| Frequency band RFID |

125 kHz |

| Transmitter output RFID, maximum |

-6 dB/m |

| Housing construction form |

Block |

| Installation conditions (mechanical) |

not flush |

| Sensor topology |

Sensor for series wiring |

| Housing material |

Plastic, thermoplastic, self-extinguishing |

| Active area |

Glass-fibre, thermoplastic |

| Reaction time, maximum |

100 ms |

| Duration of risk, maximum |

200 ms |

| Reaction time, switching off safety outputs via actuator, maximum |

100 ms |

| Gross weight |

121 g |

General data - Features

| Diagnostic output |

Yes |

| Short circuit detection |

Yes |

| Cross-circuit detection |

Yes |

| Series-wiring |

Yes |

| Safety functions |

Yes |

| Cascadable |

Yes |

| Integral system diagnostics, status |

Yes |

| Number of LEDs |

3 |

| Number of semi-conductor outputs with signaling function |

1 |

| Number of poles |

5 |

| Number of fail-safe digital outputs |

2 |

| Safety classification |

| Vorschriften |

EN ISO 13849-1 EN IEC 61508 |

| Performance Level, up to |

e |

| Category |

4 |

| PFH value |

6.80 x 10⁻¹⁰ /h |

| PFD value |

1.20 x 10⁻⁴ |

| Safety Integrity Level (SIL), suitable for applications in |

3 |

| Mission time |

20 Year(s) |

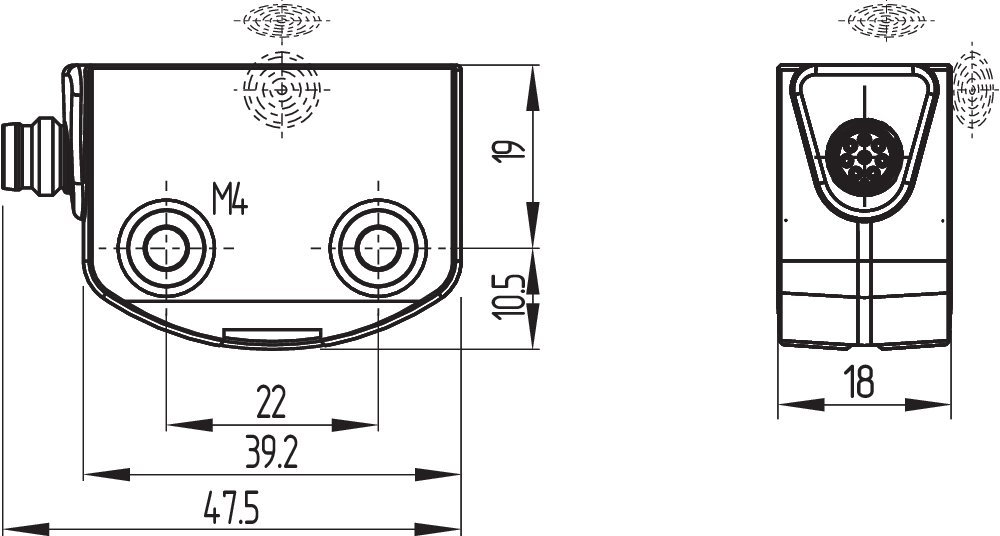

Mechanical data

| Actuating panels |

lateral front side |

| Active area |

lateral front |

| Mounting |

A 20 mm screw length usually suffices to mount the sensor. When the mounting plates are used, we recommend 25 mm long screws. |

| Type of the fixing screws |

2x M4 |

| Tightening torque of the fixing screws, maximum |

0.8 Nm |

Mechanical data - Switching distances

| Typical switching distance, frontal |

12 mm |

| Typical switching distance, lateral |

9 mm |

| Assured switching distance "ON", frontal |

10 mm |

| Assured switching distance "OFF", frontal |

18 mm |

| Assured switching distance "ON", lateral |

6 mm |

| Assured switching distance "OFF", lateral |

15 mm |

| Note (Sao) |

The specifications of the safety switching distance Sao refer to a temperature range of |

| Note (switching distance) |

All switching distances in accordance EN IEC 60947-5-3 Axial misalignment, a horizontal and vertical misalignment of the safety sensor and the actuator are tolerated. The possible misalignment depends on the distance of the active surfaces of the sensor and the actuator. The sensor remains active within the tolerance range. |

| Hysteresis (Switching distance), maximum |

2 mm |

| Repeat accuracy R |

0.5 mm |

| Note (Repeat accuracy R) |

Axial offset: The long side allows for a maximum height misalignment (x) of sensor and actuator of 8 mm (e.g. mounting tolerance or due to guard door sagging). The axial misalignment (y) is max. ± 18 mm (see figure: Operating principle).Minimum clearance between two sensor systems 100 mm |

Mechanical data - Connection technique

| Note (length of the sensor chain) |

Cable length and cross-section change the voltage drop dependiing on the output current |

| Note (series-wiring) |

Unlimited number of devices, oberserve external line fusing, max. 31 devices in case of serial diagnostic SD |

| Termination |

Connector M12, 5-pole, A-coded |

Mechanical data - Dimensions

| Length of sensor |

29.5 mm |

| Width of sensor |

39.2 mm |

| Height of sensor |

18 mm |

Ambient conditions

| Degree of protection |

IP65 IP67 |

| Ambient temperature |

-28 ... +65 °C |

| Storage and transport temperature |

-28 ... +85 °C |

| Relative humidity, maximum |

93 % |

| Note (Relative humidity) |

non-condensing non-icing |

| Resistance to vibrations |

10 … 55 Hz, amplitude 1 mm |

| Restistance to shock |

30 g / 11 ms |

| Permissible installation altitude above sea level, maximum |

2,000 m |

Ambient conditions - Insulation values

| Rated insulation voltage Ui |

32 VDC |

| Rated impulse withstand voltage Uimp |

0.8 kV |

| Overvoltage category |

III |

| Degree of pollution |

3 |

Electrical data

| Operating voltage |

24 VDC -15 % / +10 % (stabilised PELV power supply) |

| Operating current, minimum |

0.5 mA |

| No-load supply current I0, typical |

35 mA |

| Rated operating voltage |

24 VDC |

| Operating current |

600 mA |

| Required rated short-circuit current |

100 A |

| Time to readiness, maximum |

2,000 ms |

| Switching frequency, maximum |

1 Hz |

| Utilisation category DC-12 |

24 VDC / 0.05 A |

| Electrical fuse rating, maximum |

2 A |

Electrical data - Safety digital inputs

| Designation, Safety inputs |

X1 and X2 |

| Current consumption of the safety inputs |

5 mA |

| Test pulse duration, maximum |

1 ms |

| Test pulse interval, minimum |

100 ms |

| Classification ZVEI CB24I, Sink |

C1 |

| Classification ZVEI CB24I, Source |

C1 C2 C3 |

Electrical data - Safety digital outputs

| Designation, Safety outputs |

Y1 and Y2 |

| Rated operating current (safety outputs) |

250 mA |

| Output current, (fail-safe output), maximum |

0.25 A |

| Design of control elements |

short-circuit proof, p-type |

| Voltage drop Ud, maximum |

1 V |

| Leakage current Ir, maximum |

0.5 mA |

| Voltage, Utilisation category DC-12 |

24 VDC |

| Current, Utilisation category DC-12 |

0.25 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

0.25 A |

| Test pulse interval, typical |

1000 ms |

| Test pulse duration, maximum |

1 ms |

| Classification ZVEI CB24I, Source |

C2 |

| Classification ZVEI CB24I, Sink |

C1 C2 |

Electrical data - Diagnostic outputs

| Designation, Diagnostic outputs |

OUT |

| Operating current |

50 mA |

| Voltage drop Ud, maximum |

2 V |

| Voltage, Utilisation category DC-12 |

24 VDC |

| Current, Utilisation category DC-12 |

0.05 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

0.05 A |

Electrical data - Electromagnetic compatibility (EMC)

| Interfering radiation |

IEC 61000-6-4 |

Status indication

| Note (LED switching conditions display) |

LED yellow: Operating condition LED green: Supply voltage LED red: Fault |

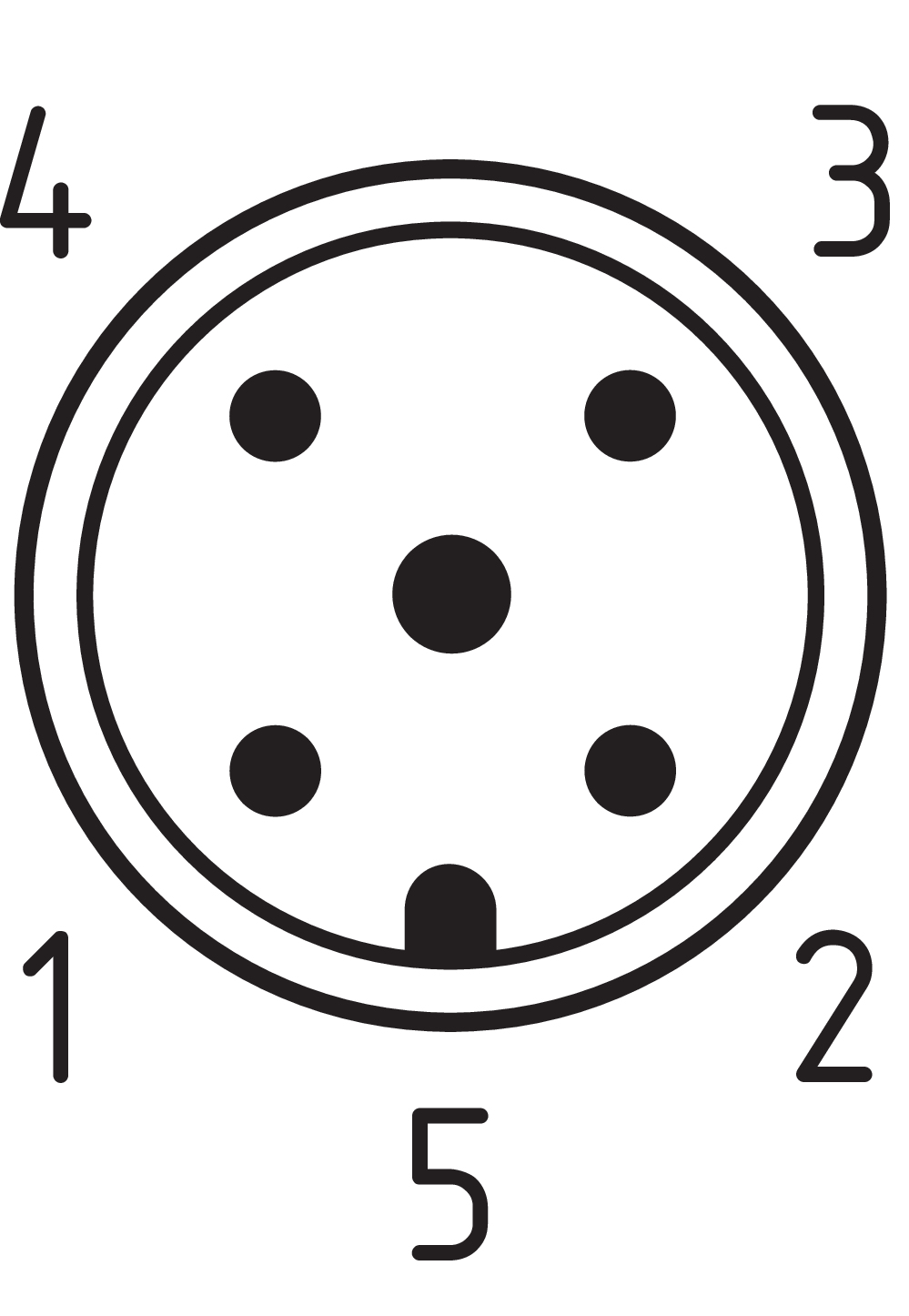

Pin assignment

| PIN 1 |

A1 Supply voltage UB |

| PIN 2 |

Y2 Safety output 2 |

| PIN 3 |

A2 GND |

| PIN 4 |

Y1 Safety output 1 |

| PIN 5 |

OUT Diagnostic output |

Scope of delivery

| Scope of delivery |

Actuator must be ordered separately. |

Accessory

| Recommendation (actuator) |

RST16-1 RST-U-2 RST260-1 |

| Recommended safety switchgear |

SRB-E-301ST SRB-E-201LC |

Language filter

Datasheet

Operating instructions and Declaration of conformity

UL Certificate

FCC-Zertifikat

IC-Zertifikat

ANATEL certification

TÜV certification

Brochure

SISTEMA-VDMA library

Download the latest version of Adobe Reader

Product picture (catalogue individual photo)

Dimensional drawing basic component

Contact arrangement

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | RSS260 |

| Type: | See ordering code |

| Description of the component: | Non-contact safety sensor |

| Relevant Directives: | Machinery Directive | 2006/42/EC |

| RED-Directive | 2014/53/EU | |

| RoHS-Directive | 2011/65/EU |

| Applied standards: | EN 60947-5-3:2013 EN 300 330 V2.1.1:2017 EN ISO 14119:2013 EN ISO 13849-1:2023 EN 61508 parts 1-7:2010 |

| Notified body for Type Examination: | TÜV Rheinland Industrie Service GmbH Am Grauen Stein, 51105 Köln ID n°: 0035 |

| EC-Type Examination Certificate: | 01/205/5348.04/25 |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, January 9, 2025 |

|

| Authorised signature Philip Schmersal Managing Director |

| UK Declaration of Conformity |  |

| Company: | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby, under sole responsibility, certify that the hereafter described components both in their basic design and construction conform to the relevant statutory requirements, regulations and designated standards of the United Kingdom. |

| Name of the component: | RSS260 |

| Type: | See ordering code |

| Description of the component: | Non-contact safety sensor |

| Relevant legislation: | Supply of Machinery (Safety) Regulations | 2008 |

| Radio Equipment Regulations | 2017 | |

| The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations | 2012 |

| Designated standards: | EN 60947-5-3:2013 EN 300 330 V2.1.1:2017 EN ISO 14119:2013 EN ISO 13849-1:2015 IEC 61508 parts 1-7:2010 |

| Approved body for Type Examination: | TÜV Rheinland UK Ltd. 1011 Stratford Road Solihull, B90 4BN ID: 2571 |

| Type examination certificate: | 01/205U/5348.00/22 |

| UK-Importer / Person authorised for the compilation of the technical documentation: | Schmersal UK Ltd. Paul Kenney Unit 1, Sparrowhawk Close Enigma Business Park Malvern, Worcestershire, WR14 1GL |

| Place and date of issue: | Wuppertal, November 2, 2022 |

|

| Authorised signature Philip Schmersal Managing Director |

K.A. Schmersal GmbH & Co. KG, Möddinghofe 30, 42279 Wuppertal

The details and data referred to have been carefully checked. Images may diverge from original. Further technical data can be found in the manual. Technical amendments and errors possible.

Generated on: 18/07/2025, 01:30

.png?id=bb44e9061d048e5250879d3fc4285be0)