AZ 16-02ZVK-STL- 1476-2/2430

AZ 16-02ZVK-STL- 1476-2/2430

| Produkt-typebetegnelse: AZ 16-(1)ZV(2)K-(3)-(4)-(5) |

| (1) | |

| uten | 1 NO-kontakt / 1 NC-kontakt |

| 02 | 2 NC-kontakter |

| 03 | 3 NC-kontakter |

| 12 | 1 NO-kontakter / 2 NC-kontakt |

| (2) | |

| uten | Tilbakefjæringskraft |

| R | Holdekraft 30 N |

| (3) | |

| G24 | med LED (bare tilgjengelig for versjoner med en NO- og en NC-kontakt.) |

| (4) | |

| M16 | Kabelinngang M16 |

| M20 | Kabelinngang M20 |

| ST | Stik M12, 4-polet, nede |

| STL | Stik M12, 4-polet, venstre |

| STR | Stik M12, 4-polet, høyre |

| (5) | |

| 2254 | Holdekraft 5 N |

| 1762 | Frontmontering |

| 1637 | gullbelagte kontakter |

- Plast bryterhus

- dobbel isolering

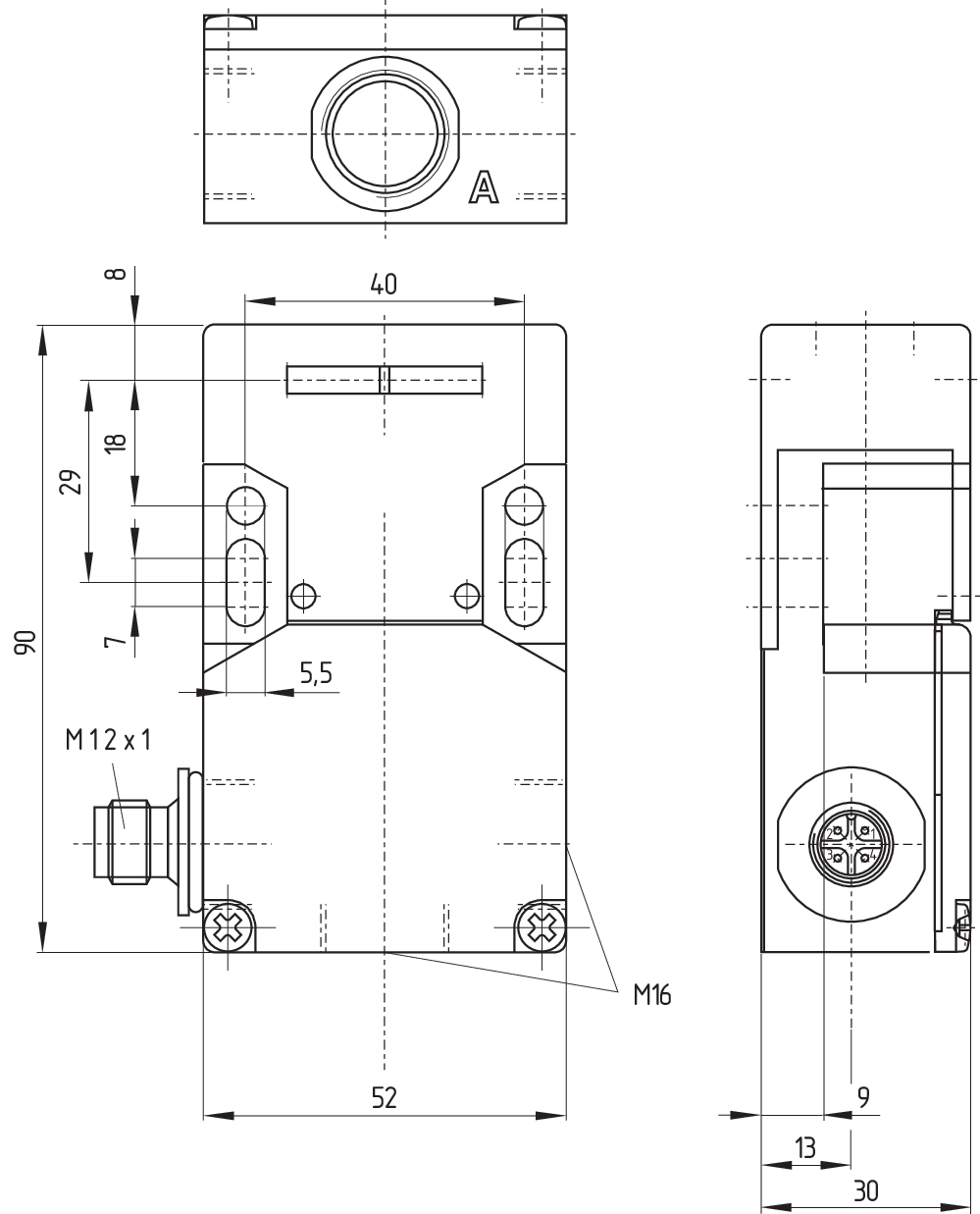

- 52 mm x 90 mm x 30 mm

- Flerkoding

- Lang levetid

- Høy kontaktpålitelighet med lave spenninger og strømstyrker

- Ufølsom overfor tilsmussing

- Slissehull for justering, runde hull for lokalisering

Bestillingsinformasjon

| Produkt-typebetegnelse |

AZ 16-02ZVK-STL- 1476-2/2430 |

| Artikkelnummer (bestillingsnummer) |

101170142 |

| EAN (European Article Number) |

4030661297279 |

| eCl@ss number, version 12.0 |

27-27-26-02 |

| eCl@ss number, version 11.0 |

27-27-26-02 |

| eCl@ss-nummer, versjon 9.0 |

27-27-26-02 |

| ETIM number, version 7.0 |

EC002592 |

| ETIM number, version 6.0 |

EC002592 |

Tillatelser - Standard

|

cULus |

Gobale egenskaper

| Standard |

EN ISO 13849-1 EN ISO 14119 EN IEC 60947-5-1 |

| Kodenivå i henhold til ISO 14119 |

lav |

| Aktivt prinsipp |

elektromekanisk |

| Kapslingsmateriale |

Plast, glassfiber forsterket termoplast, selvslukkende |

| Bruttovekt |

122 g |

Gobale egenskaper - Karakteristikker

| Tilbakefjæringskraft |

Ja |

| Antall aktiveringsretninger |

3 |

| Antall sikkerhetskontakter |

2 |

| Antall kabelgjennomføringer |

3 |

Klassifisering

| Standarder, forskrifter |

EN ISO 13849-1 |

| Performance Level, up to |

c |

| Kontrollkategori iht. EN ISO 13849 |

1 |

| B10D Normally-closed contact (NC) |

2 000 000 bevegelser |

| Note |

Electrical life on request. |

| B10D Normally-open contact (NO) |

1 000 000 bevegelser |

| Note |

at 10% Ie and ohmic load |

| Mission time |

20 år |

Klassifisering - Feilutelukkelse

| Please note: |

Can be used when fault exclusion for dangerous damage to the 1-channel mechanism is permissible and sufficient protection against manipulation is guaranteed. |

| Performance Level, up to |

d |

| Category |

3 |

| Note |

for 2-channel use and with suitable logic unit. |

| Mission time |

20 år |

Mekaniske data

| Mekanisk levetid, minimum |

1 000 000 bevegelser |

| tvangsbrytende vandring |

8 mm |

| Positive break force per NC contact, minimum |

10 N |

| Tvangsbrytende kraft, minimum |

20 N |

| Aktueringshastighet, maksikum |

2 m/s |

| Montering |

Skruer |

| Type of the fixing screws |

2x M6 |

Mechanical data - Connection technique

| Connector position |

Venstre |

| Kabelføring |

M12 (A-kodet) |

| Konnektor stikk |

Konnektorplugg M12, 4-polet, A-koding |

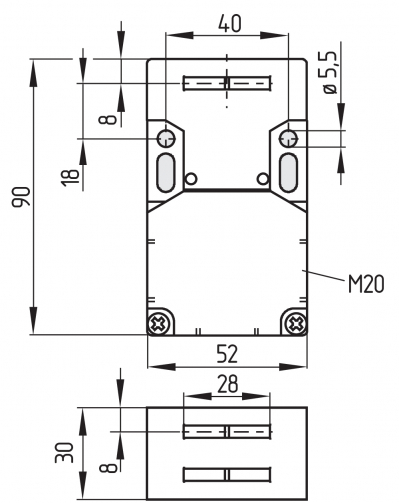

Mekaniske data - mål

| Lengde på sensor |

30 mm |

| Bredde på sensor |

52 mm |

| Høyde på sensor |

90 mm |

Omgivelsesbetingelser

| Tetthetsgrad |

IP67 |

| Ambient temperature |

-30 ... +80 °C |

| Storage and transport temperature |

-40 ... +85 °C |

| Permissible installation altitude above sea level, maximum |

2 000 m |

Ambient conditions - Insulation values

| Isolasjonsspenning |

500 V |

| Nominell impulsmotstandsspenning |

6 kV |

| Overvoltage category |

III |

| Forurensningsgrad iht. IEC/EN 60664-1 |

3 |

| Rated impulse withstand voltage, connector 4-pole |

2.5 kV |

Elektriske data

| Termisk teststrøm |

10 A |

| Nødvendig nominell kortslutningsstrøm iht EN 60947-5-1 |

1 000 A |

| Koblingselement |

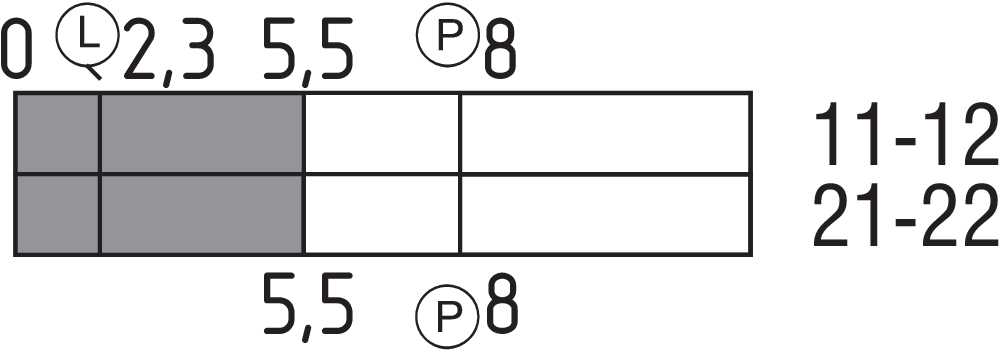

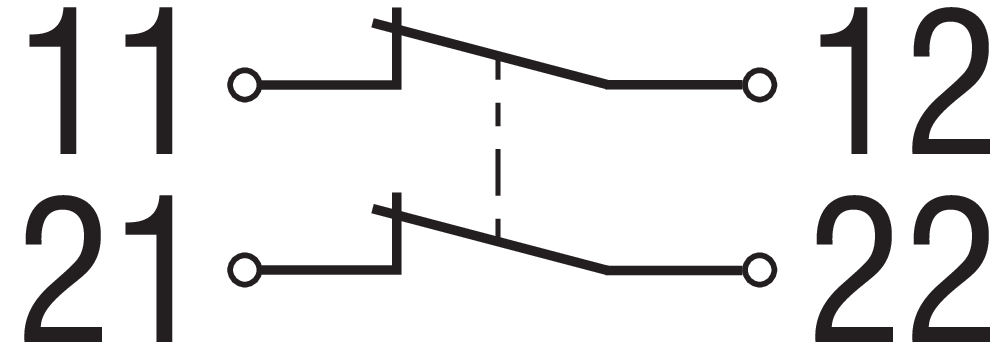

2 NC-kontakter |

| Bryteprinsipp |

slow action, positive break NC contact |

| koplingsfrekvens |

4 000 /h |

| Materiale for kontakter, elekrisk |

Sølv |

Elektriske data - Sikkerhetskontakter

| Voltage, Utilisation category AC-15 |

230 VAC |

| Current, Utilisation category AC-15 |

4 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

4 A |

| Note, Utilisation category DC-13 |

Connector 4-pole |

Elektriske data - Hjelpekontaktene

| Voltage, Utilisation category AC-15 |

230 VAC |

| Current, Utilisation category AC-15 |

4 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

4 A |

| Note, Utilisation category DC-13 |

Connector 4-pin |

inkludert ved levering

| inkludert ved levering |

Slot covers for dust-proof covering of the openings not in use |

Språk filter

Datablad

Operating Instructions and Declaration of Conformity (Short)

UL sertifikat

SISTEMA-VDMA Bibliotek/Library

Last ned den nyeste versjonen av Adobe Reader

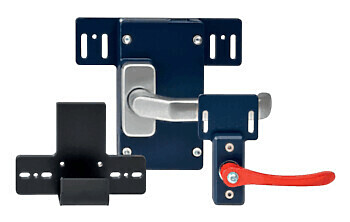

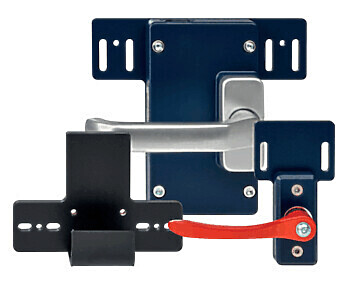

Produktbilde (enkelt katalogbilde)

Dimensjonsriktig tegning grunnenhet

Brytervandringsdiagram

Innholdsfortegnelse

- 1 About this document

- 1.1 Function

- 1.2 Target group of the operating instructions: authorised qualified personnel

- 1.3 Explanation of the symbols used

- 1.4 Appropriate use

- 1.5 General safety instructions

- 2 Product description

- 2.1 Ordering code

- 2.2 Special versions

- 2.3 Purpose

- 2.4 Warning about misuse

- 2.5 Exclusion of liability

- 2.6 Technical Data

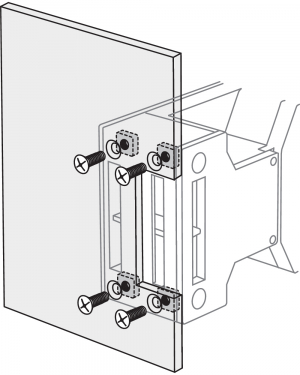

- 3 Mounting

- 3.1 General mounting instructions

- 3.2 Mounting of the actuator

- 3.3 Dimensions

- 4 Electrical connection

- 4.1 General information for electrical connection

- 4.2 Contact Options

- 5 Set-up and maintenance

- 6 Disassembly and disposal

- 6.1 Disassembly

- 6.2 Disposal

1 About this document

1.1 Function

This document provides all the information you need for the mounting, set-up and commissioning to ensure the safe operation and disassembly of the switchgear. The operating instructions enclosed with the device must always be kept in a legible condition and accessible.

1.2 Target group of the operating instructions: authorised qualified personnel

All operations described in the operating instructions manual must be carried out by trained specialist personnel, authorised by the plant operator only.

Please make sure that you have read and understood these operating instructions and that you know all applicable legislations regarding occupational safety and accident prevention prior to installation and putting the component into operation.

The machine builder must carefully select the harmonised standards to be complied with as well as other technical specifications for the selection, mounting and integration of the components.

The information contained in this operating instructions manual is provided without liability and is subject to technical modifications.

1.3 Explanation of the symbols used

- Information, hint, note: This symbol is used for identifying useful additional information.

- Caution: Failure to comply with this warning notice could lead to failures or malfunctions.

Warning: Failure to comply with this warning notice could lead to physical injury and/or damage to the machine.

1.4 Appropriate use

The Schmersal range of products is not intended for private consumers.

The products described in these operating instructions are developed to execute safety-related functions as part of an entire plant or machine. It is the responsibility of the manufacturer of a machine or plant to ensure the correct functionality of the entire machine or plant.

The safety switchgear must be exclusively used in accordance with the versions listed below or for the applications authorised by the manufacturer. Detailed information regarding the range of applications can be found in the chapter "Product description".

1.5 General safety instructions

The user must observe the safety instructions in this operating instructions manual, the country specific installation standards as well as all prevailing safety regulations and accident prevention rules.

- Further technical information can be found in the Schmersal catalogues or in the online catalogue on the Internet: products.schmersal.com.

2 Product description

2.1 Ordering code

| Product type description: AZ 16-(1)ZV(2)K-(3)-(4)-(5) |

| (1) | |

| without | 1 NO contact/1 NC contact |

| 02 | 2 NC contact |

| 03 | 3 NC contact |

| 12 | 1 NO contact/2 NC contacts |

| (2) | |

| without | Ejection force |

| R | Latching force 30 N |

| (3) | |

| G24 | with LED (only available for version with one NO and one NC contact) |

| (4) | |

| M16 | cable entry M16 |

| M20 | Cable entry M20 |

| ST | Connector M12, 4 pole, bottom |

| STL | Connector M12, 4 pole, left |

| STR | Connector M12, 4 pole, right |

| (5) | |

| 2254 | Latching force 5 N |

| 1762 | Front mounting |

| 1637 | Gold-plated contacts |

2.2 Special versions

For special versions, which are not listed in the ordering code, these specifications apply accordingly, provided that they correspond to the standard version.

2.3 Purpose

The safety switches with separate actuator are suitable for sliding, hinged and removable safety guards, which need to be closed in order to ensure the necessary operational safety.

The safety switches are used for applications, in which the hazardous situation is terminated without delay when the safety guard is opened.

When the safety guard is opened, the NC contacts are positively opened and the NO contacts are closed.

- The safety switchgears are classified according to EN ISO 14119 as type 2 interlocking devices.

- The user must evaluate and design the safety chain in accordance with the relevant standards and the required safety level.

- The entire concept of the control system, in which the safety component is integrated, must be validated to the relevant standards.

2.4 Warning about misuse

- In case of improper use or manipulation of the safety switchgear, personal hazards or damages to machinery or plant components cannot be excluded. There are no residual risks, provided that the safety instructions as well as the instructions regarding mounting, commissioning, operation and maintenance are observed.

2.5 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from defective mounting or failure to comply with the operating instructions manual. The manufacturer shall accept no liability for damages resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary repairs, conversions and modifications to the device are strictly forbidden, the manufacturer shall accept no liability for damages resulting from such invasive work, arbitrary repairs, conversions and/or modifications to the device.

2.6 Technical Data

Tillatelser - Standard

|

cULus |

Gobale egenskaper

| Standard |

EN ISO 13849-1 EN ISO 14119 EN IEC 60947-5-1 |

| Kodenivå i henhold til ISO 14119 |

lav |

| Aktivt prinsipp |

elektromekanisk |

| Kapslingsmateriale |

Plast, glassfiber forsterket termoplast, selvslukkende |

| Bruttovekt |

122 g |

Gobale egenskaper - Karakteristikker

| Tilbakefjæringskraft |

Ja |

| Antall aktiveringsretninger |

3 |

| Antall sikkerhetskontakter |

2 |

| Antall kabelgjennomføringer |

3 |

Klassifisering

| Standarder, forskrifter |

EN ISO 13849-1 |

| Performance Level, up to |

c |

| Kontrollkategori iht. EN ISO 13849 |

1 |

| B10D Normally-closed contact (NC) |

2 000 000 bevegelser |

| Note |

Electrical life on request. |

| B10D Normally-open contact (NO) |

1 000 000 bevegelser |

| Note |

at 10% Ie and ohmic load |

| Mission time |

20 år |

Klassifisering - Feilutelukkelse

| Please note: |

Can be used when fault exclusion for dangerous damage to the 1-channel mechanism is permissible and sufficient protection against manipulation is guaranteed. |

| Performance Level, up to |

d |

| Category |

3 |

| Note |

for 2-channel use and with suitable logic unit. |

| Mission time |

20 år |

Mekaniske data

| Mekanisk levetid, minimum |

1 000 000 bevegelser |

| tvangsbrytende vandring |

8 mm |

| Positive break force per NC contact, minimum |

10 N |

| Tvangsbrytende kraft, minimum |

20 N |

| Aktueringshastighet, maksikum |

2 m/s |

| Montering |

Skruer |

| Type of the fixing screws |

2x M6 |

Mechanical data - Connection technique

| Connector position |

Venstre |

| Kabelføring |

M12 (A-kodet) |

| Konnektor stikk |

Konnektorplugg M12, 4-polet, A-koding |

Mekaniske data - mål

| Lengde på sensor |

30 mm |

| Bredde på sensor |

52 mm |

| Høyde på sensor |

90 mm |

Omgivelsesbetingelser

| Tetthetsgrad |

IP67 |

| Ambient temperature |

-30 ... +80 °C |

| Storage and transport temperature |

-40 ... +85 °C |

| Permissible installation altitude above sea level, maximum |

2 000 m |

Ambient conditions - Insulation values

| Isolasjonsspenning |

500 V |

| Nominell impulsmotstandsspenning |

6 kV |

| Overvoltage category |

III |

| Forurensningsgrad iht. IEC/EN 60664-1 |

3 |

| Rated impulse withstand voltage, connector 4-pole |

2.5 kV |

Elektriske data

| Termisk teststrøm |

10 A |

| Nødvendig nominell kortslutningsstrøm iht EN 60947-5-1 |

1 000 A |

| Koblingselement |

2 NC-kontakter |

| Bryteprinsipp |

slow action, positive break NC contact |

| koplingsfrekvens |

4 000 /h |

| Materiale for kontakter, elekrisk |

Sølv |

Elektriske data - Sikkerhetskontakter

| Voltage, Utilisation category AC-15 |

230 VAC |

| Current, Utilisation category AC-15 |

4 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

4 A |

| Note, Utilisation category DC-13 |

Connector 4-pole |

Elektriske data - Hjelpekontaktene

| Voltage, Utilisation category AC-15 |

230 VAC |

| Current, Utilisation category AC-15 |

4 A |

| Voltage, Utilisation category DC-13 |

24 VDC |

| Current, Utilisation category DC-13 |

4 A |

| Note, Utilisation category DC-13 |

Connector 4-pin |

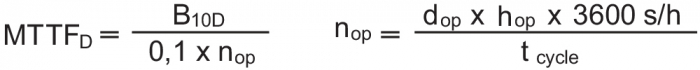

Note about the safety classification

Basically suitable up to Cat. 1 / PL c.

With 2-channel usage with fault exclusion mechanism (if a fault exclusion to the 1-channel mechanics is authorised) and suitable logic applicable up to Cat. 3 / PL d

(Determined values can vary depending on the application-specific parameters hop, dop and tcycle as well as the load.)

If multiple safety components are wired in series, the Performance Level to EN ISO 13849-1 will be reduced due to the restricted error detection under certain circumstances.

3 Mounting

3.1 General mounting instructions

- Please observe the relevant requirements of the standards ISO 12100, ISO 14119 and ISO 14120.

The mounting dimensions are indicated on the rear of the component. The enclosure must not be used as an end stop.

Any mounting position. The mounting position however must be chosen so that the ingress of dirt and soiling in the used opening is avoided. The unused openings must be sealed by means of slot sealing plugs (AZ 15/16 - 1476-1 available as accessory) after fitting.

3.2 Mounting of the actuator

See operating instructions Actuator.

- The actuator must be permanently fitted to the safety guards and protected against displacement by suitable measures (tamperproof screws, gluing, drilling of the screw heads).

| Actuating radii [mm] |  |  | ||

|---|---|---|---|---|

| over the small edge of the actuator | over the wide edge of the actuator | |||

| Rmin | d | Rmin | d | |

| AZ 15/16-B2 | - | - | 45 | 11 |

| AZ 15/16-B2-1747 | - | - | 45 | 11 |

| AZ 15/16-B3 | 32 | 11 | - | - |

| AZ 15/16-B3-1747 | 32 | 11 | - | - |

| AZ 15/16-B6 | 25 | 11 | 38 | 11 |

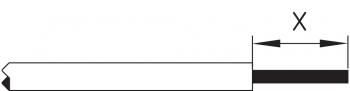

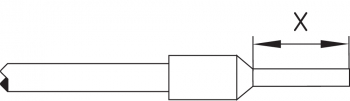

3.3 Dimensions

All measurements in mm.

4 Electrical connection

4.1 General information for electrical connection

- The electrical connection may only be carried out by authorised personnel in a de-energised condition.

The contact labelling can be found in the wiring compartment of the switch. Appropriate cable glands with a suitable degree of protection are to be used.

Settle length x of the conductor: 6 mm

After wiring, dust and soiling must be removed from the wiring compartment. The safety switch is double insulated. The use of a protective ground connector therefore is not authorised.

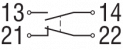

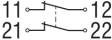

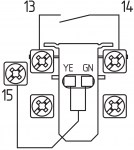

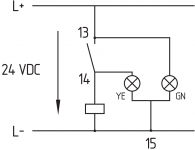

4.2 Contact Options

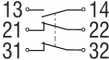

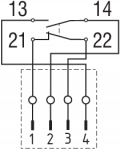

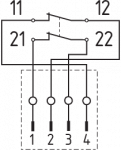

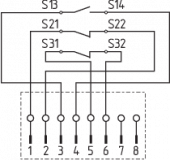

Contacts are shown with safety guard closed. All NC contacts have positive break B.

| AZ 16ZV.K | AZ 16-02ZV.K | AZ 16-12ZV.K |

|---|---|---|

|  |  |

| AZ 16-03ZV.K | AZ 16ZV.K-ST | AZ 16-02ZV.K-ST |

|---|---|---|

|  |  |

| AZ 16-12ZV.K-ST | LED | LED |

|---|---|---|

|  |  |

| Key | |

|---|---|

| B | Automatic opener, NC contact |

| Normally-open contact |

| Normally-closed contact |

5 Set-up and maintenance

The safety function of the safety components must be tested. In the case of correct installation and adequate use, the safety switchgear features maintenance-free functionality. A regular visual inspection and functional test, including the following steps, is recommended:

- Check for free movement of the actuating element

- Check cable entry and connections

- Check the switch enclosure for damage

- Remove particles of dust and soiling

- Adequate measures must be taken to ensure protection against tampering either to prevent tampering of the safety guard, for instance by means of replacement actuators.

- Damaged or defective components must be replaced.

6 Disassembly and disposal

6.1 Disassembly

The safety switchgear must be disassembled in a de-energised condition only.

6.2 Disposal

- The safety switchgear must be disposed of in an appropriate manner in accordance with the national prescriptions and legislations.

| EU Declaration of Conformity |  |

| Original | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby certify that the hereafter described components both in their basic design and construction conform to the applicable European Directives. |

| Name of the component: | AZ 15 AZ 16 |

| Type: | See ordering code |

| Description of the component: | Positive break position switch with separate actuator for safety functions |

| Relevant Directives: | Machinery Directive | 2006/42/EC |

| RoHS-Directive | 2011/65/EU |

| Applied standards: | EN 60947-5-1:2017 ISO 14119:2013 |

| Person authorised for the compilation of the technical documentation: | Oliver Wacker Möddinghofe 30 42279 Wuppertal |

| Place and date of issue: | Wuppertal, August 3, 2020 |

|

| Authorised signature Philip Schmersal Managing Director |

| UK Declaration of Conformity |  |

| Company: | K.A. Schmersal GmbH & Co. KG Möddinghofe 30 42279 Wuppertal Germany Internet: www.schmersal.com |

| Declaration: | We hereby, under sole responsibility, certify that the hereafter described components both in their basic design and construction conform to the relevant statutory requirements, regulations and designated standards of the United Kingdom. |

| Name of the component: | AZ 15 AZ 16 |

| Type: | See ordering code |

| Description of the component: | Positive break position switch with separate actuator for safety functions |

| Relevant legislation: | Supply of Machinery (Safety) Regulations The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations | 2008 2012 |

| Designated standards: | EN 60947-5-1: 2017 ISO 14119: 2013 |

| UK-Importer / Person authorised for the compilation of the technical documentation: | Schmersal UK Ltd. Paul Kenney Unit 1, Sparrowhawk Close Enigma Business Park Malvern, Worcestershire, WR14 1GL |

| Place and date of issue: | Wuppertal, October 28, 2022 |

|

| Authorised signature Philip Schmersal Managing Director |

Schmersal Nordiska AB, F O Petersons gata 28, S-421 31 Västra Frölunda

Data og verdier er kontrollert omhyggelig. Bilder kan avvike fra originalen. Ytterligere tekniske data finner du i manualen. Tekniske modifiseringer og feil kan forkomme.

Generert til 19.01.2025, 17:26

.png?id=aad13e08b1c8f1adbb3bc1b36a87ee65)